One of the foundations of every economy is the engineering sector, which creates cutting-edge equipment, facilities, and technology for use in a range of manufacturing and service industries. Therefore it is right to say that the engineering sector is quite important to other industries.

Engineering organizations are at the forefront of innovation as the world witnesses the miracles of Industry. This reality makes the ERP software more important than ever for the engineering sector.

Today, eresource Xcel is one of the most favoured ERP system among all major engineering comp... Read More

Inventory control

Engineering companies will have precise information about their needs and future projections of how much more they will require thanks to eresource Xcel ERP. Additionally, it will monitor current data as well as effective stock selection and delivery procedures.

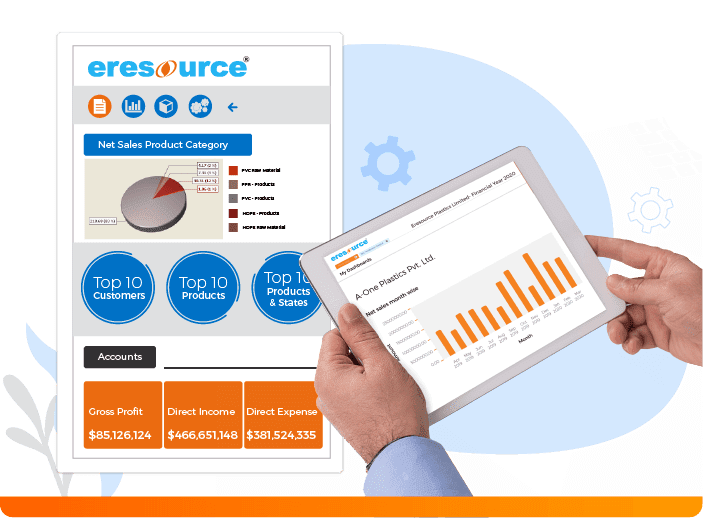

Financial Management

Engineering projects have high expenses, so it’s critical to monitor them daily to make sure money is spent wisely and prevent financial resources from being wasted. ERP helps you keep track of and manage all of your company’s ... Read More

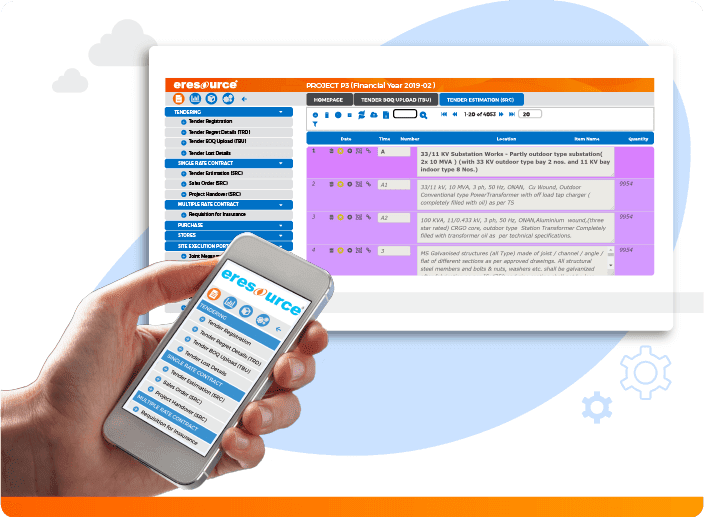

An ERP system needs to have a few key components in order to function well. For engineering firms, eresource Xcel ERP software comes with built-in features. You can modify the system and add features to get additional functionality. These six essential characteristics are a must for any ERP software.

Integration with third parties

There is no department or vendor segregated because eresource Xcel is known to improve collaboration with internal and external stakeholders. As a result, this ERP provides real-time data access and collaboration.

Modu... Read More

One of the key strategic issues in engineering companies is design of the product for manufacturability. This involves forming integrated design teams, pulling together product design, engineering and manufacturing. This strategy also must be kept in mind about – reducing order-to-delivery cycle time; high level of after -sales customer support for maintenance, shorter design and cycle time, globally coordinated flexible manufacturing and globally coordinated research and development. The presence of an effective ERP system is required to successfully implement the above strategies and eresource Xcel is the right answer.

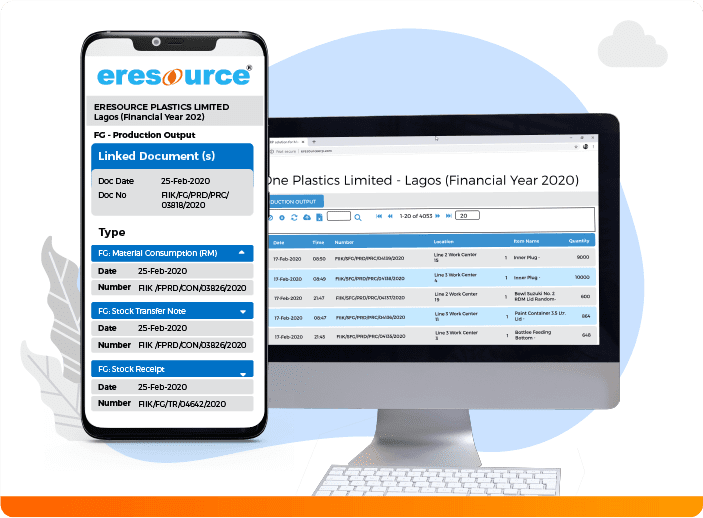

A integrated web-based ERP software provides a degree of interoperability that was difficult and expensive to achieve with standalone, custom-built systems. eresource’s web-based ERP serves many industries and numerous functional areas in an integrated fashion and automate operations from supply chain management, inventory control, manufacturing scheduling and production, sales support, customer relationship management, financial and cost accounting, human resources and almost any other data-oriented management process.

With an ERP system like eresource, business operations have become much easier. For example, when a salesperson enters an order in the field, the transaction can immediately flow through to other functional areas both within and external to the firm. The order might trigger an immediate change in production plans, inventory stock levels or employees’ schedules, or lead to the automated generation of invoices and credit evaluations for the customer and purchase orders from suppliers.

Every growing organization must realize that ERP systems have become the most significant IT investment for most companies in their capital budgeting.

As far as any business is concerned, customer demand is by far the most influential factor. Manufacturing industry is one of the businesses that strive to make a nation grow with its contribution to the national economy. And a country that gives priority to its manufacturing sector could achieve success in its mission to bring the country into the mainstream of world business. India’s new initiative in this phase, ‘Made in India’, is moving in the right direction with many overseas companies are finding our nation as a fertile soil to manufacture their goods indigenously.

eresource, a purely indigenous Manufacturing ERP Software, is contributing largely into the growth of manufacturing business by providing one of the excellent technology. When the automation becomes way of life no companies can keep away from this technological advantage. Understanding the need of every industry, eresource has come out with industry specific ERP system for every industry verticals and ‘eresource Xcel’ is an exclusive ERP for manufacturing industry. eresource Xcel, a viable ERP system that has been integrated with all essential modules for manufacturing industry.

Following are some of the prime advantages of eresource Xcel,