The greatest difficulty for industrial item manufacturers is managing the constant barrage of variety, complexity, and change.

All industries in the manufacturing sector need to be up to date with the newest technological support to survive and thrive in today’s cutthroat business environment.

Furthermore, the success of companies producing industrial goods depends on their enterprise resource planning (ERP) system. There is no need to second guess yourself because eresource Xcel ERP system’s ability to maintain industry best practices in the face of evolving and new problems is what will determine the Industrial Products company’s growth and long-term survival.

For manufacturers of industrial items, managing the constant barrage of variety, complexity, and change presents the greatest difficulty. Demand for modern, up-to-date product diversity, that too at a reduced price, and with robust performance throughout the life cycle. The maker of industrial equipment faces a challenging environment due to price pressure and innovation driven by global competition.

Manufacturers of industrial items also have additional challenges. That’s consumer expectations for greater value at lower prices when using an ERP system with comprehensive services and support.

The process of making industrial goods operates differently. The products are usually purchased from multiple outside sources and include a large number of sophisticated components. The entire life cycle performance, which encompasses all the activities that take place from the equipment’s creation to its eventual replacement, has replaced the outdated simple quality measures in the past, significantly altering the way that items are quality managed.

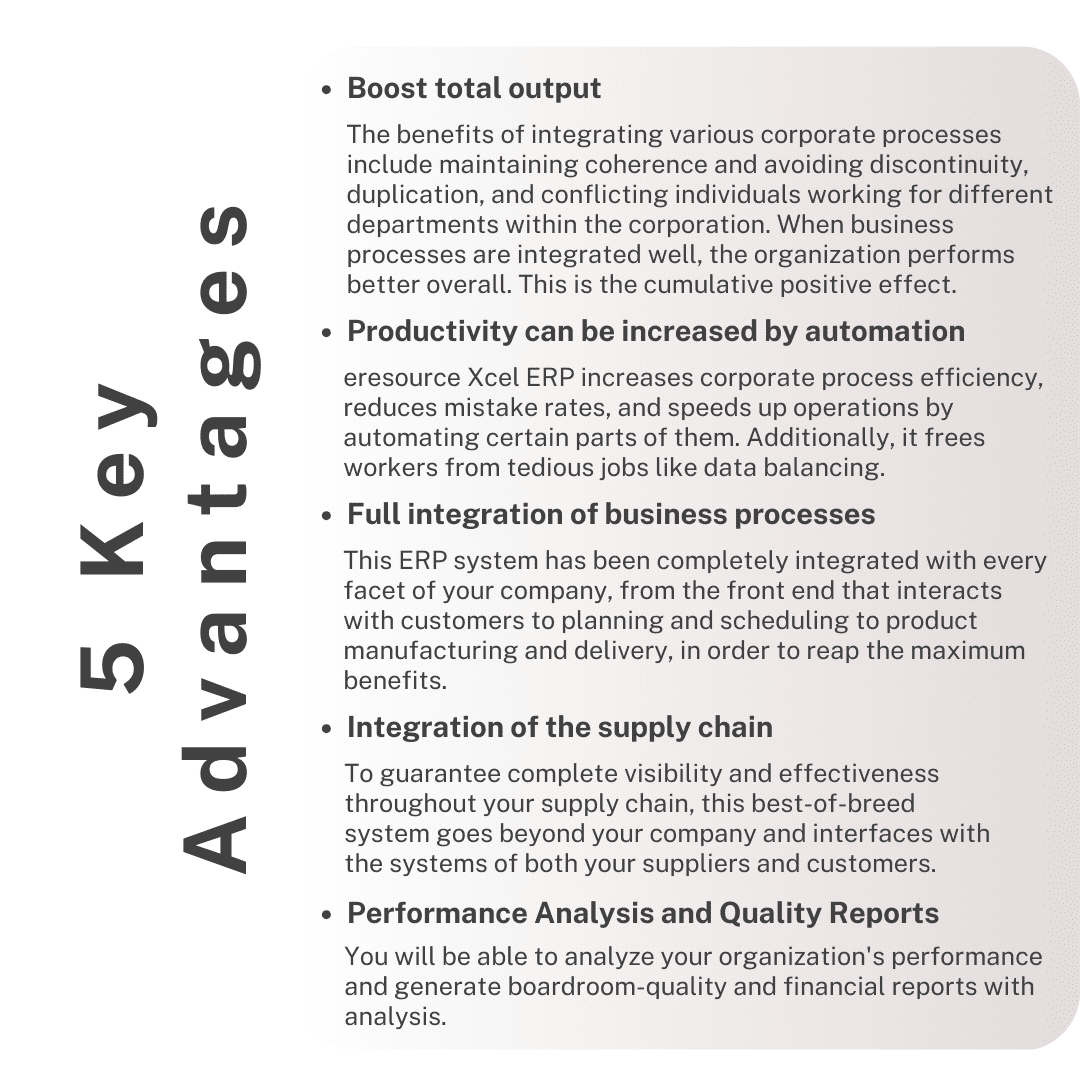

eresource Xcel ERP’s advantages for the industrial products industry are

1. The ability to quickly modify prices in reaction to rising supplier costs

2. Utilize quick access to critical performance indicators to make decisions in real-time

3. Total inventory visibility to satisfy market and customer demands

4. Boost your company’s online visibility to combat the danger of online competition

5. Streamline manual operations and handle backorder processing more effectively

6. Automate credit control to lighten the workload of accounts personnel and expedite payments

eresource Xcel ERP for Manufacturing Machinery

With eresource Xcel, the ERP solution designed specifically for machinery manufacturers, businesses can effectively handle every facet of their supply chain and logistics. Manufacturers of industrial machinery frequently have to regulate the issuance of components at particular routing stages of their manufacturing process. This system allows for the configuration of routings to guarantee that, upon release and completion of the production work order, components are issued to the appropriate work center.

When work centres are designated as component issue locations, components issued to a work order can be configured to clear the backlog at the work order receipt or particular routing operation steps. A copy of the normal routing for the parent item is automatically sent to work orders in the eresource Xcel ERP system.

To create unique ‘as constructed’ versions of an item, routings can be changed on the work order without affecting the regular routing.

The only ERP system designed specifically for manufacturers, eresource Xcel, integrates and automates key business functions including scheduling operations, accepting orders from customers, and maintaining inventory and financial records. This has the potential to significantly increase any organization’s effectiveness.

eresource Xcel ERP in the manufacturing of machinery: What are the advantages?

For more information and a LIVE DEMO of our ERP for Industrial Product Manufacturing, please write to us now: sales@eresourceinfotech.com

Categories

Register for Free Demo!

Recent Post

-

eresource ERP 360 - an

11th Apr 2019 -

A competitive ERP system for

17th Apr 2019 -

Auto components manufacturing industry has

17th Apr 2019 -

Make the best use of

17th Apr 2019