Investing in an ERP System must be taken with some serious thoughts. Once implemented the system must serve the company for years to come. It must also reflect how you do business today yet evolve through subsequent business practice changes.

An ERP system in a process manufacturing company depends on data from every corner of the business. The process starts from the collection of bulk drugs. A bulk drug also known as active pharmaceutical ingredient (API) is a chemical molecule in a pharmaceutical product that lends the product the claimed therapeutic effect.

These ingredi... Read More

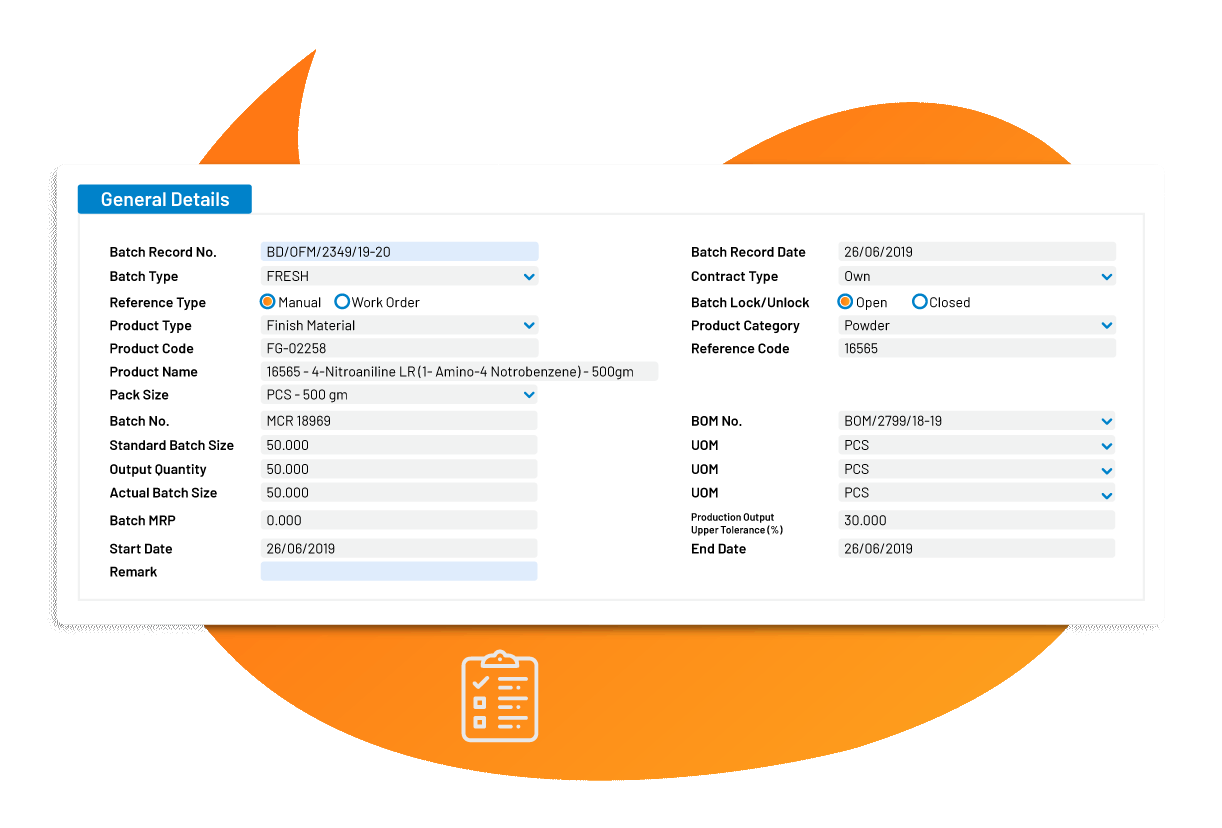

An ERP system like eresource Bpro, which is a specially designed application to management batch manufacturing or process manufacturing also takes care of Bulk drug management along with other functional operations such as inventory receipts, quality assurance test results, production records, customer orders, payments from customers, payments for purchases, shipments and invoices, maintenance of equipment and facilities, investments as well as several others heads under taxes. Therefore it is very important that the ERP system must be designed to reflect very need of the company’s bu... Read More

Innovations and developments over the past few years in the Information Technology have resulted in a reduction in labor, and the widespread use of process control instruments. This has affected in the bulk drugs process too. These developments have increased information flow between the plant floor and the ERP system. eresource Bpro provides required support to your business process a smooth and steady progress. eresource’s web-based ERP system enables the real-time, bulk drugs and plant floor information to control information in a manufacturing environment.

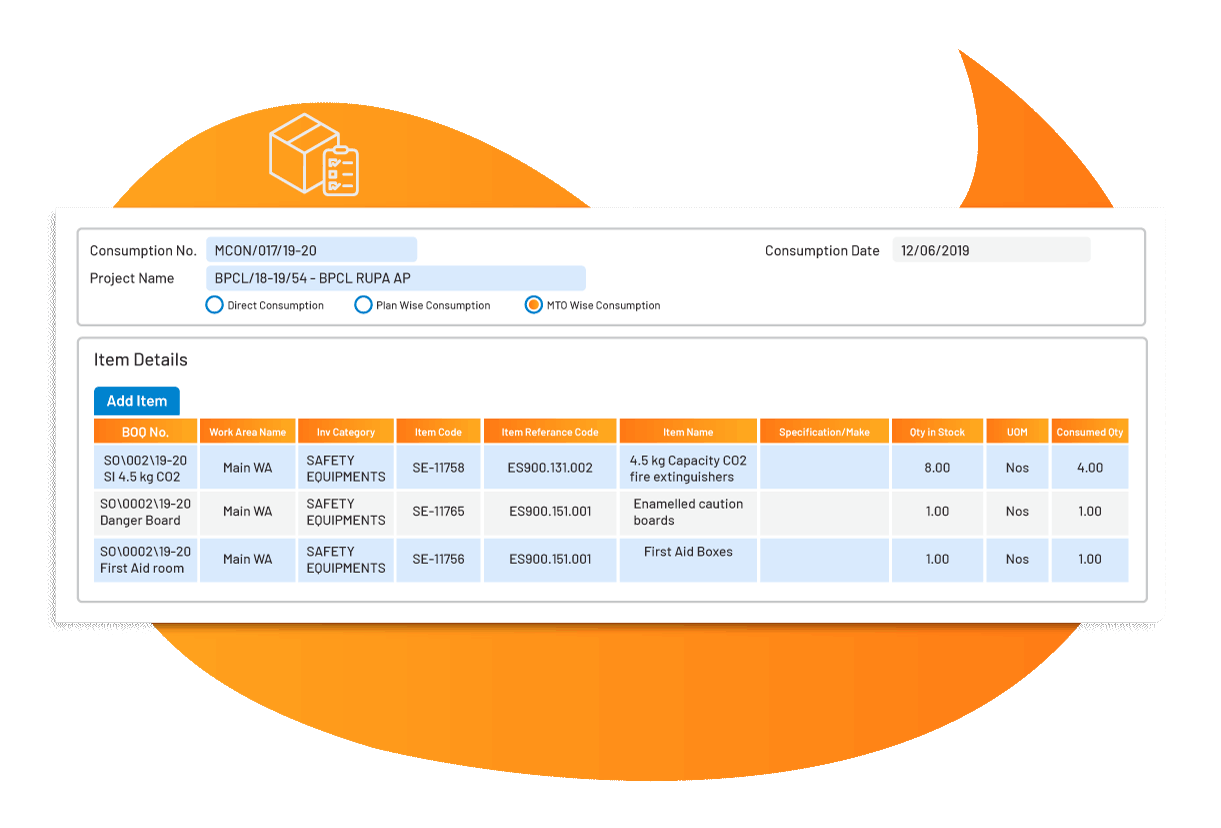

In a process industry ERP system, factory floor is always on the focus, specifically on the operator/user who is the most intelligent agent in a manufacturing environment. With eresource Bpro ERP system implemented, automatic data capture provides real-time updates to your inventory, improving the speed, ease, and accuracy of data capture. Each operator/user is connected through the ERP system, to everyone else in the plant floor, and to all plant floors within the organization. This operations-centric manufacturing environment-where information is shared within and between plants and plann... Read More

What is most important is that with eresource Bpro ERP system all your production including the management of bulk drug process and all other manufacturing process are easily integrated and it enables automatic data collection. When you implement eresource Bpro you have an ERP system that is agile, adaptable, and easy to link with everyone in the organization.

In a process industry ERP software, factory floor is always on the focus, specifically on the operator/user who is the most intelligent agent in a manufacturing environment. With an ERP system implemented, automatic data capture provides real-time updates to your inventory, improving the speed, ease, and accuracy of data capture. Each operator/user is connected through the ERP system, to everyone else in the plant floor, and to all plant floors within the organization. This operations-centric manufacturing environment-where information is shared within and between plants and planning in real time – is truly the efficient supply chain.

Innovations and developments over the past few years in the Information Technology have resulted in a reduction in labor, and the widespread use of process control instruments. These developments have increased information flow between the plant floor and the ERP system. ERP provides required support to business process in a smooth and steady manner. And the system also enables the real-time, plant floor information to control information in a manufacturing environment.

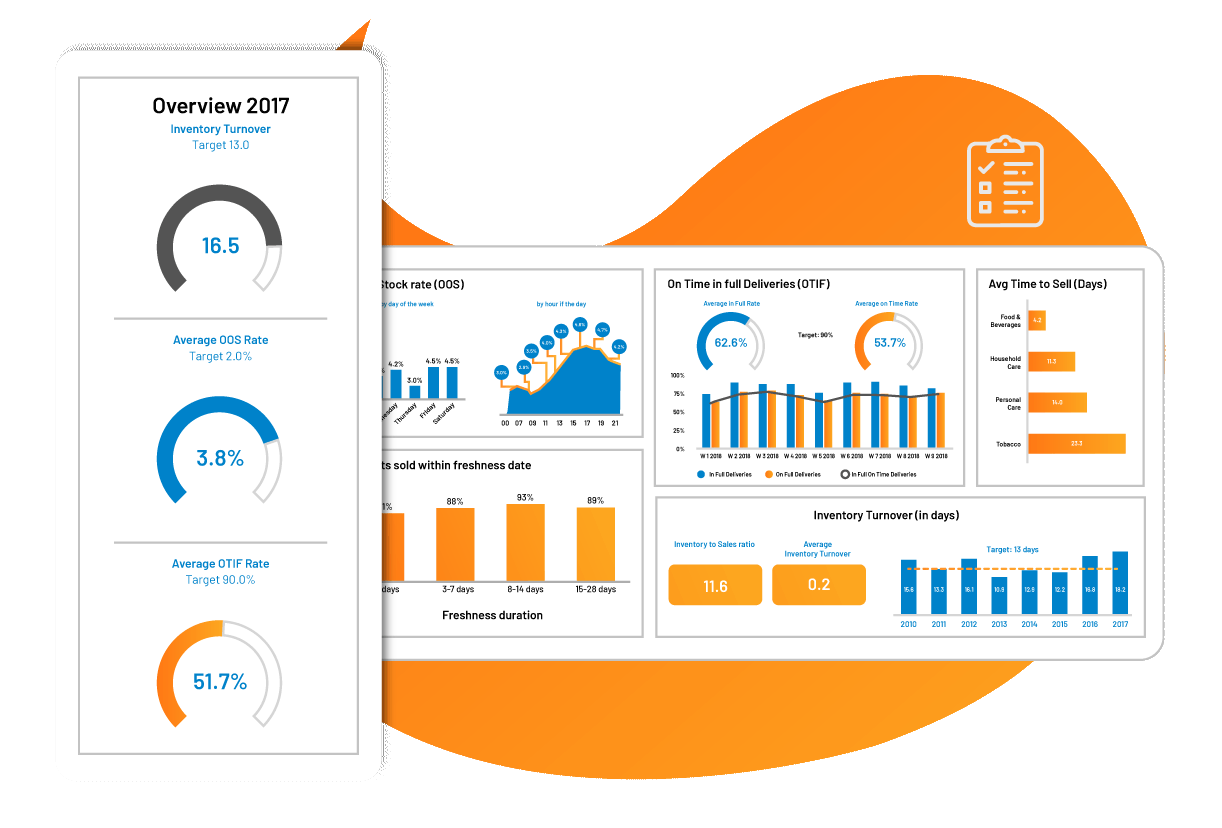

By leveraging eresource Bpro ERP for Process Manufacturing, companies can boost their competitive position. Through benefits such as optimizing production, ensuring compliance and presenting a more environmentally conscious brand to their customers, companies can attract more clients while also gaining revenue through increased efficiency. eresource Bpro ERP system’s automation capabilities and reduced spoilage are just a few of the many factors that can make your day-to-day processes easier while also optimizing opportunities for revenue.

The bread and butter of any business is ensuring that your efforts are generating a profit. With cost tracking and profitability measurement tools, you can use the often complex information regarding the cost of materials for recipes and formulas to measure revenue and other financial factors. eresource Bpro ERP Process manufacturing system could track ingredient costs based on chemical characteristics such as potency and the quantity that’s used. Additionally, the system enables to measure and calculate how much wasted ingredients and raw materials cost your business.

Following are some of the prime benefits of eresource Bpro,

• Optimizes the inventory

• Easily accessible

• Provides a more precise overview to help make business decisions quickly

• Improves planning of production

• Reduces administrative costs

• Keeps the process regulatory compliant

• Handles all the accounts and finance reports