Automate and centralize financial operations. The system connects production and inventory with accounting for accurate, real-time financial reporting.

Key Features:

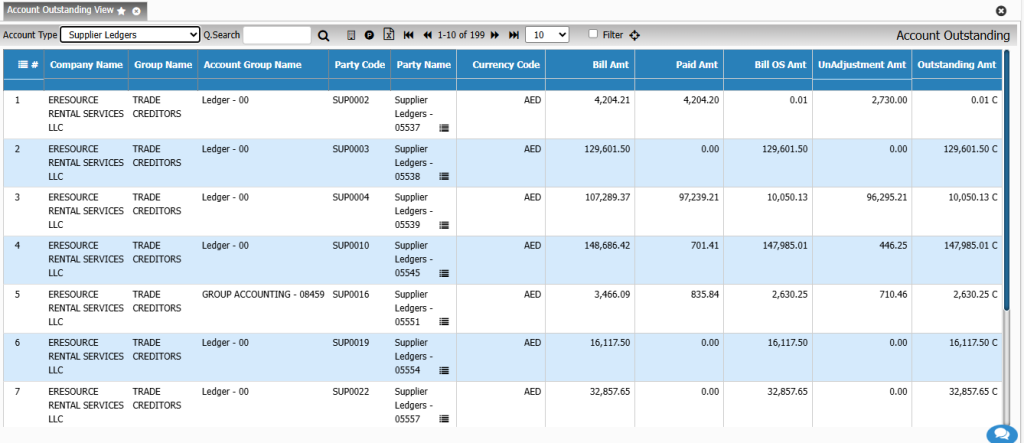

• General ledger, AR, AP, cash, bank, budgeting

• Multi-currency support

• Financial consolidation across plants

• Automatic postings from inventory and production

One ERP. Every Industry. Global Presence. Powered by Azaalea AI

One ERP. Every Industry. Global Presence. Powered by

ERP for Personal Care Products Industry

Think of eresource Bpro when your personal care product business needs a facelift

ERP for Personal Care Products Industry

Think of eresource Bpro when your personal care product business needs a facelift

Bpro ERP

About the Industry

The personal care products industry demands strict control over formulations, ingredient safety, hygiene practices, allergen tracking, and compliance with cosmetic and healthcare regulations. Manufacturers handle sensitive ingredients such as emollients, surfactants, botanical extracts, fragrances, preservatives, essential oils, and active compounds. Managing batch production, filling lines, packaging, labeling, and multi-stage quality checks manually often leads to inconsistencies, contamination risks, and delays.

eresource Bpro ERP is built specifically for personal care manufacturers to streamline every step of production from formulation and batch management to quality control, inventory, supply chain, and finance. It ensures smooth coordination of mixing, heating, emulsification, blending, filling, labeling, and dispatch processes.

The system supports creams, lotions, shampoos, conditioners, body wash, serums, soaps, oils, gels, masks, deodorants, and all forms of skincare and personal hygiene products. With complete traceability, robust QC, and automated compliance workflows, manufacturers can maintain product consistency and meet strict regulatory standards.

With real-time insights, automated workflows, and digital documentation, eresource Bpro ensures every batch matches defined specifications, helping companies deliver safe, effective, and high-quality personal care products at scale.

Why Choose eresource Bpro ERP for the Personal Care Products Industry?

Personal care manufacturing involves handling sensitive ingredients, maintaining hygiene standards, and meeting regulatory guidelines. Manual tracking makes it difficult to maintain batch consistency, manage allergens, and ensure accurate formulation. eresource Bpro ERP centralizes all manufacturing, quality, inventory, and financial workflows, creating an efficient and compliant production environment.

- Key Advantages:

- Manages formulations, recipes, and ingredient ratios with precision

- Tracks raw materials, allergens, and sensitive ingredients with full traceability.

- Ensures strict hygiene and QC compliance through digital lab testing.

- Supports FDA, GMP, and cosmetic industry documentation.

- Maintains warehouse hygiene, FEFO/FIFO, and temperature-controlled storage.

- Integrates costing, billing, receivables, and payables seamlessly.

With real-time visibility and controlled workflows, eresource Bpro ensures consistent, safe, and profitable personal care product manufacturing.

Core Modules

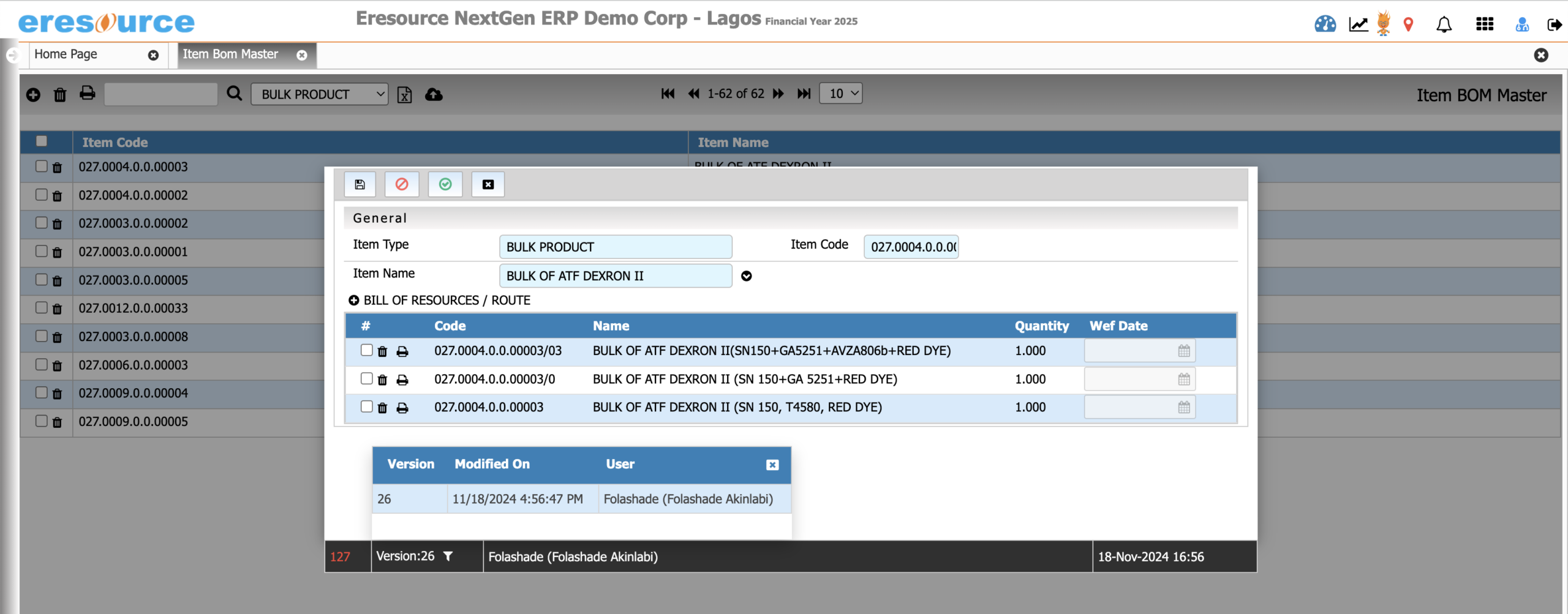

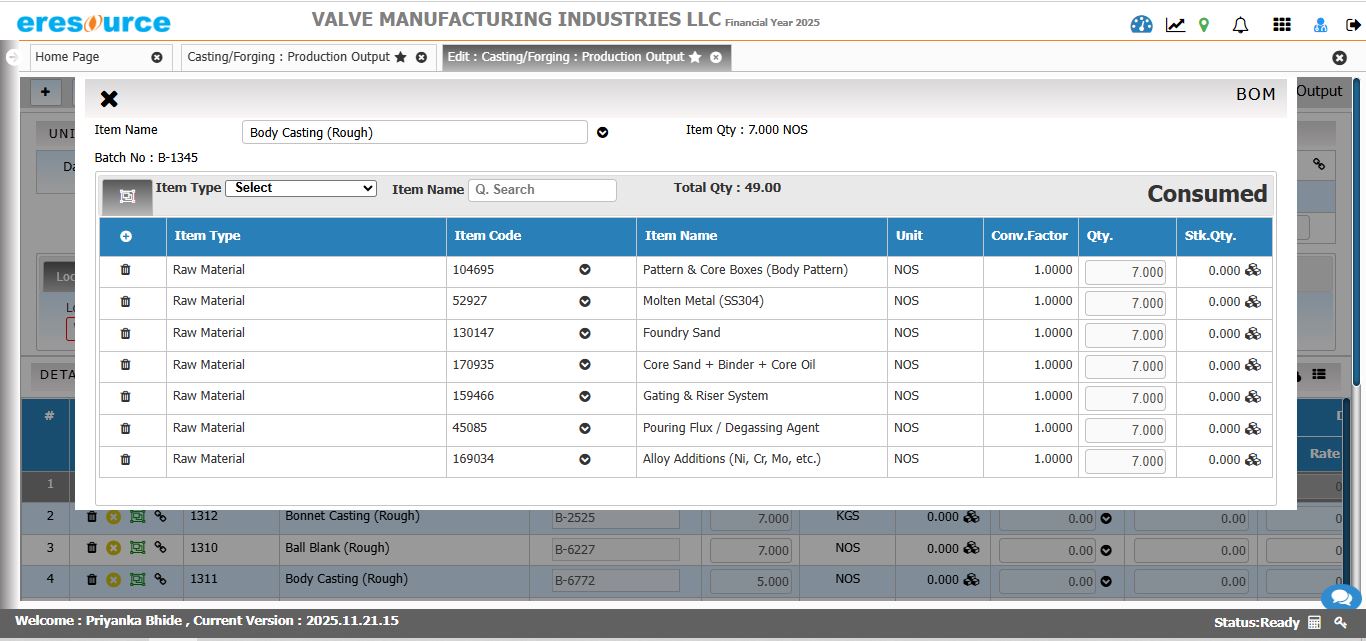

Formulation & Recipe Management

Manage every aspect of your product formulas with precision. This module helps process industries create, track, and optimize formulations while maintaining strict control over ingredients, variations, and cost impact.

Key Features:

• Multi-level formula creation with percentage or weight/volume inputs

• Alternate raw materials and potency-based adjustments

• Formula scaling for any batch size

• Revision control for formulation changes

• Restricted access for sensitive formulas

• Automatic yield, loss, overhead, and cost calculations

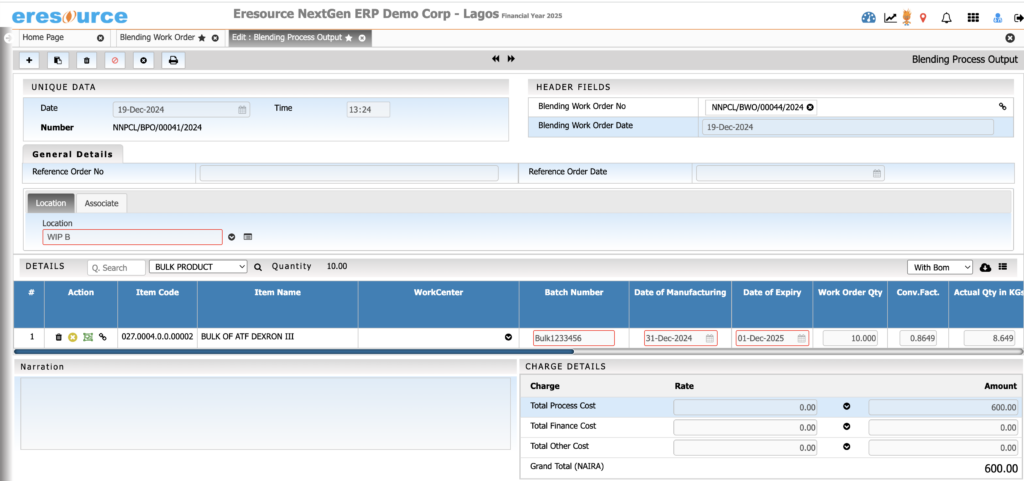

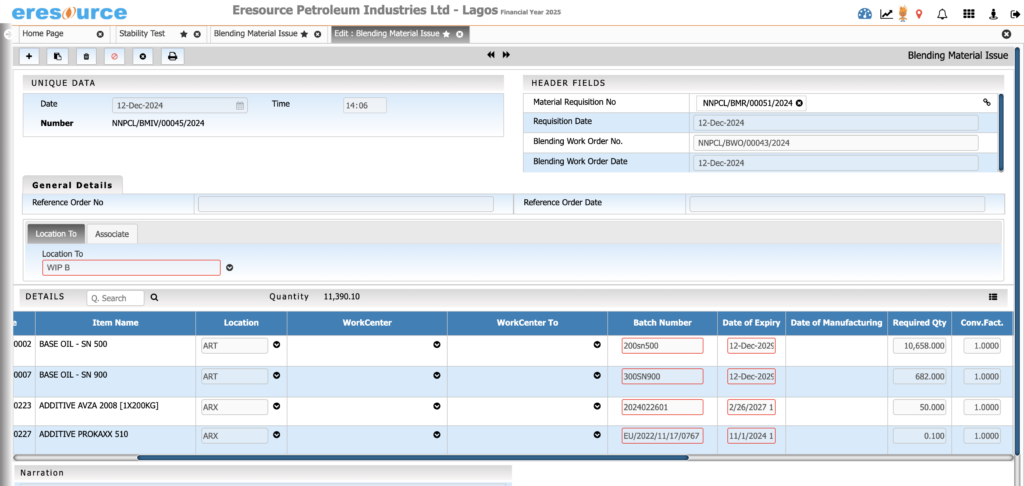

Batch Manufacturing Process

Execute batch production with complete accuracy and visibility. This module supports end-to-end batch operations and ensures compliance with regulatory requirements through detailed BMR/BPR documentation.

Key Features:

• Batch creation, scheduling, and execution

• Digital BMR and BPR tracking

• Real-time monitoring of process stages

• WIP visibility across all production points

• Auto-consumption of materials based on recipes

• Batch yield, variance, scrap, and rework recording

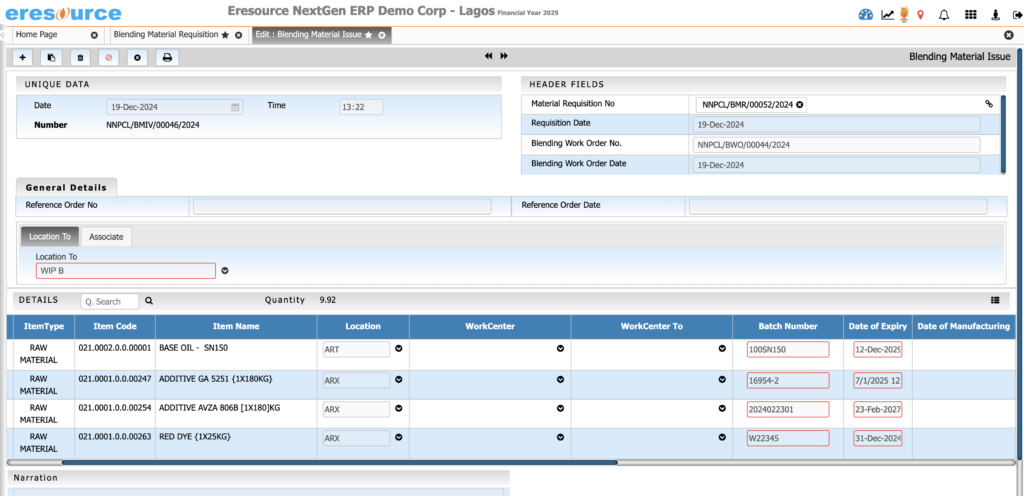

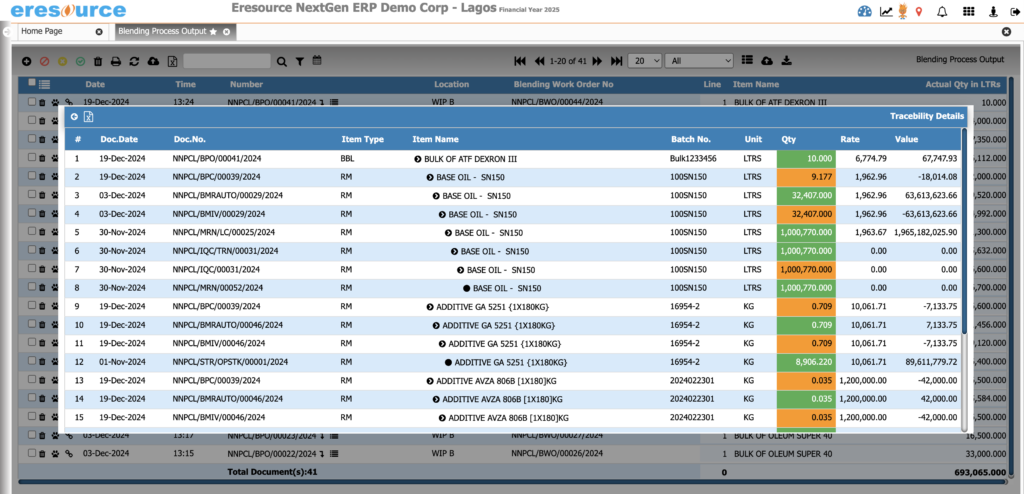

Batch Numbering & Traceability

Track every batch at every stage. This module provides full traceability from raw materials to finished products, ensuring compliance, safety, and rapid recall management.

Key Features:

• Automatic or manual batch number assignment

• Forward and backward traceability

• Complete material-to-finished-good genealogy

• Batch splitting, merging, and reclassification

• Compliance-ready traceability for pharma and food

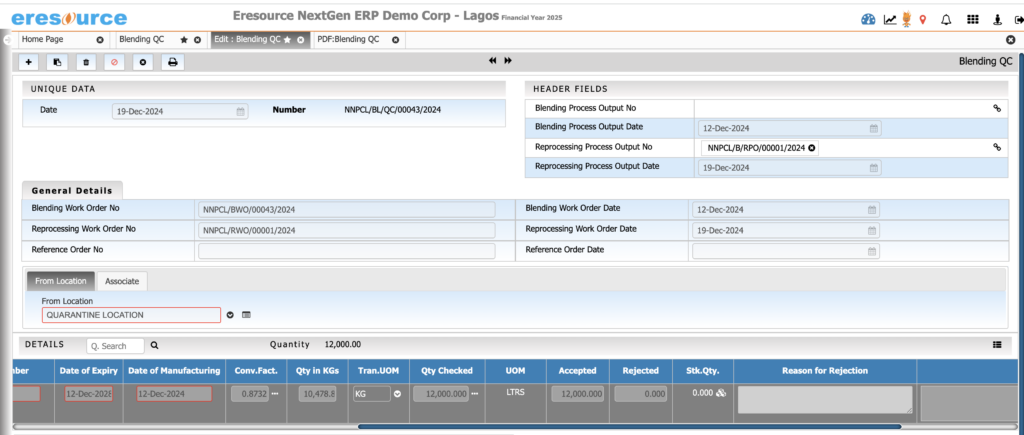

Shelf-Life & Expiry Management

Ensure material freshness and compliance by actively managing expiry timelines. The system prevents the use of expired items and improves quality control during storage and dispatch.

Key Features:

• Automated expiry and retest date calculation

• FEFO/FIFO picking

• Alerts for near-expiry materials

• Quarantine and block controls for expired items

• Automatic restrictions during production or dispatch

Batch Costing

Understand the true cost of every batch. This module delivers detailed costing insights that help manufacturers improve pricing decisions, reduce losses, and maximize profitability.

Key Features:

• Material, machine, labor, and overhead allocation

• Cost per batch, per unit, or per product variant

• Loss and wastage cost analysis

• Standard vs actual cost comparison

• Profitability tracking by batch or product line

Quality Control & Quality Assurance

Ensure consistent product quality through structured QC and QA processes. From raw materials to finished goods, the system enforces strict checks, documentation, and compliance workflows.

a) Inward Quality Control (IQC)

- QC parameters for each raw material

- Sampling plans

- Hold, pass, and reject controls

- Vendor-wise QC performance

b) In-Process Quality Control (IPQC)

- Real-time QC at every batch stage

- Viscosity, pH, density, titration tests

- Auto-restriction if QC fails

- Deviation tracking and corrective actions

c) Finished Goods QC (FGQC)

- QC testing before packaging

- COA generation

- Batch-wise retain sample management

- QA release workflows

d) Stability Testing

- Stability study scheduling

- Condition-wise test logging

- Stability-based expiry assignment

Inventory & Warehouse Management

Control your inventory with complete batch accuracy. This module ensures compliant storage, stock rotation, and material issuance for smooth and safe production cycles.

Key Features:

• Batch, grade, potency-based stock visibility

• FEFO/FIFO allocations

• Approved, rejected, and quarantine stock segregation

• Raw material issuance based on recipe

• Warehouse transfers with batch tracking

Production Planning & Scheduling

Plan production efficiently with real-time insights into capacity, availability, and demand. The system optimizes batch schedules across tanks, reactors, and processes for maximum throughput.

Key Features:

• MRP-driven raw material planning

• Reactor and vessel capacity scheduling

• Multi-level batch planning

• Automated scheduling for multi-stage processes

• Resource load balancing

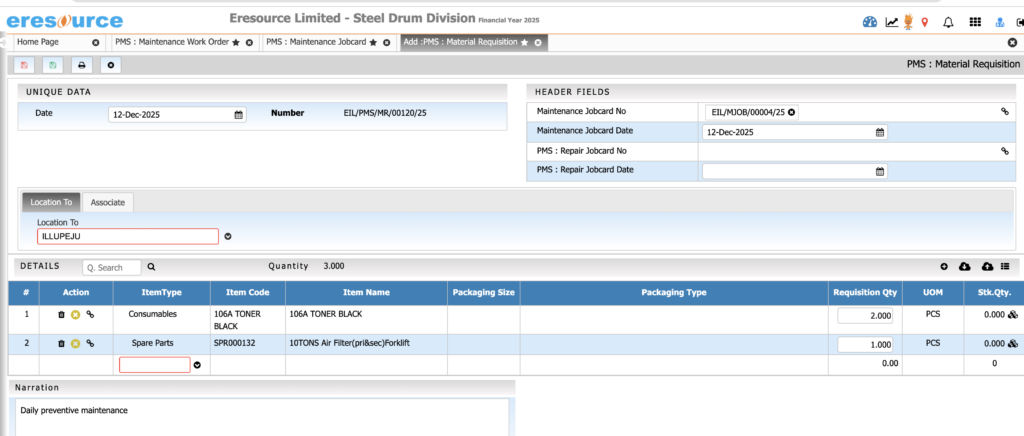

Equipment & Maintenance Management

Keep production equipment running reliably. This module reduces downtime by scheduling preventive maintenance and tracking all repairs, calibrations, and associated costs.

Key Features:

• Preventive and breakdown maintenance

• Calibration and equipment validation schedules

• Maintenance work order tracking

• Cost monitoring for maintenance tasks

• Spare parts inventory

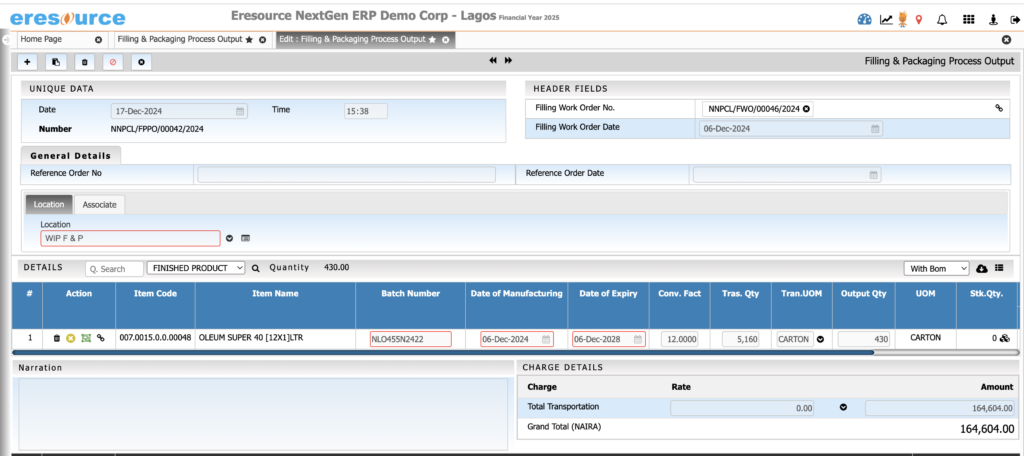

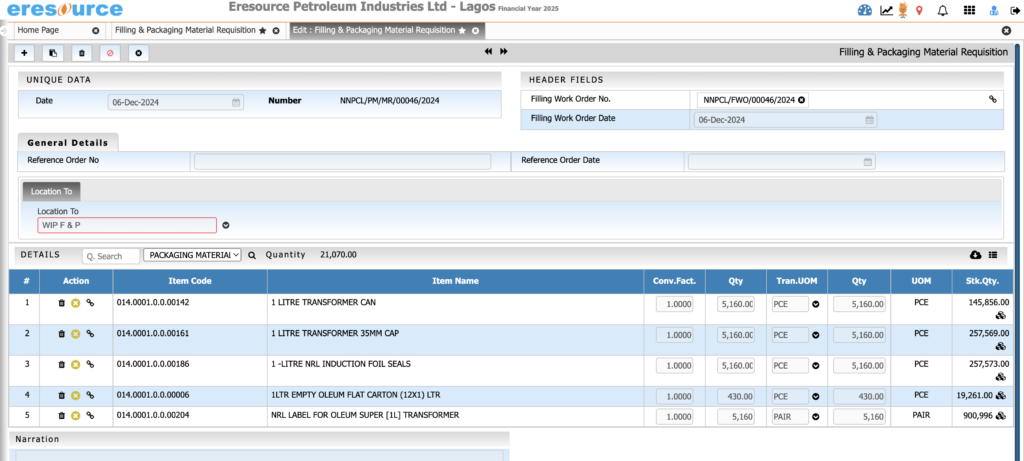

Packaging & Filling Management

Manage packaging operations seamlessly. The system supports primary and secondary packaging and ensures accurate labeling and stock deductions.

Key Features:

• Multi-stage packaging workflows

• Packaging BOM with labels, cartons, sleeves, caps

• Label printing with batch and expiry information

• Automatic consumption of packing materials

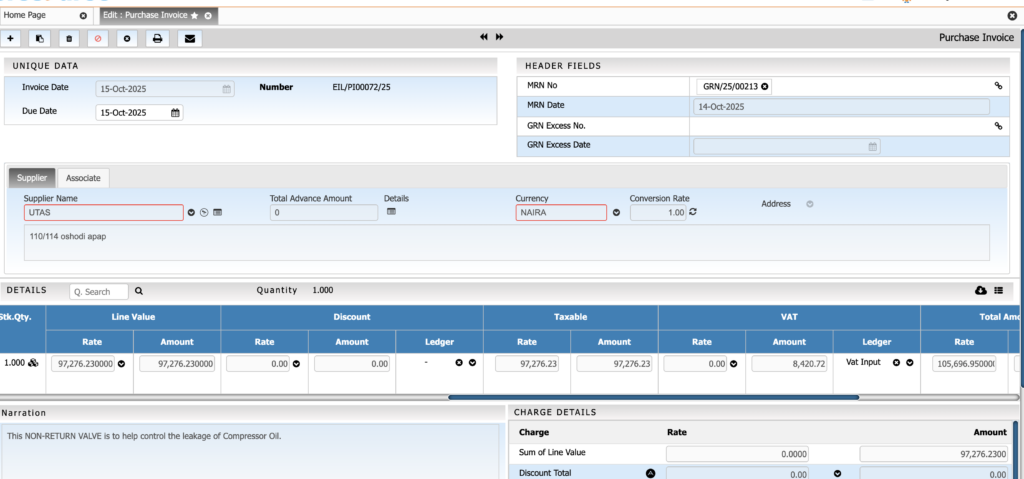

Purchase & Supplier Management

Streamline procurement with controlled and transparent purchasing processes. This module helps ensure timely availability of raw materials while maintaining vendor quality and cost efficiency.

Key Features:

• RFQ and quotation comparison

• Vendor qualification and performance tracking

• Potency-based purchase adjustments

• Purchase contracts for bulk chemicals

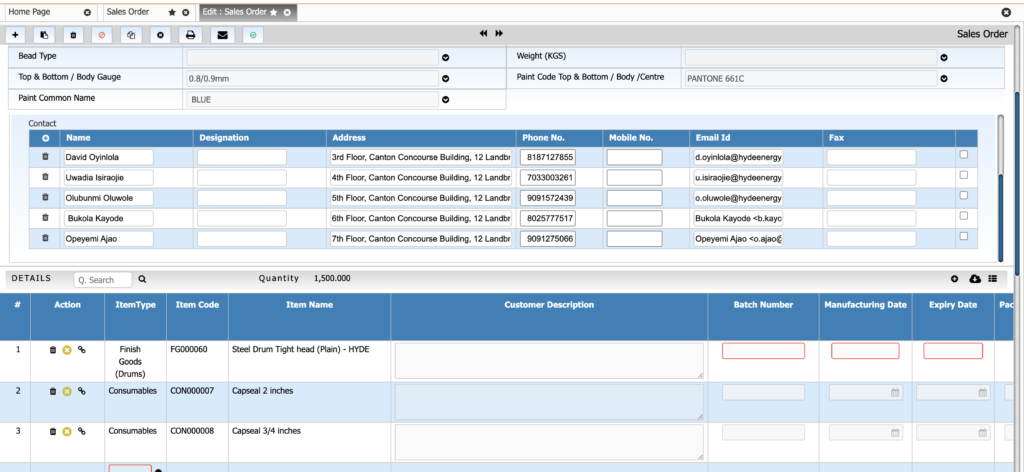

Sales & Order Management

Handle sales orders with precise control over batch selection and expiry constraints. This ensures timely dispatch and compliance with customer-specific requirements.

Key Features:

• Batch-specific order allocations

• FEFO-based batch selection

• COA attached with dispatch

• Sales forecasting linked with production

Financial Management

Costing & Profitability Analysis

Get a clear view of operational profitability. This module analyzes cost behavior across batches, products, and customers, enabling smarter financial decision-making.

Key Features:

• Activity-based costing

• Batch-wise cost variance

• Product profitability analysis

• Cost simulation for new formulations

Benefits for Personal Care Product Manufacturers

- Maintain consistent product quality with accurate formulation and QC control

- Achieve full traceability from ingredient sourcing to final packaged goods

- Reduce batch failures through strong hygiene and process monitoring

- Improve compliance with FDA, GMP, ISO, and cosmetic guidelines

- Strengthen raw material and supplier management

- Reduce wastage through optimized inventory and FEFO/FIFO

- Improve costing accuracy and financial transparency

- Scale operations across multiple product lines and production plants

Transform the Way You Produce with eresource Bpro

eresource Bpro ERP isn’t just software, it’s a catalyst for smarter batch-based manufacturing. With precise process control, real-time visibility, and cloud-ready automation, it turns complex production workflows into smooth, predictable operations.

From formulation to batching to final output, every step becomes more consistent, efficient, and optimized for growth.

Case Studies

GlowCare Cosmetics

Achieved 15% faster product changeovers through streamlined batch processing and automated recipe management.

15% Faster Changeovers

PureTouch Personal Care

Achieved 100% ingredient traceability compliance with integrated batch tracking and documentation systems.

100% Traceability

API Integrations

APIs to integrate with other enterprise, compliance, finance, analytics, or planning systems as per business needs.

Real-time data exchange with regulatory compliance platforms, laboratory information systems, and quality management tools.

IoT Integrations

Temperature and humidity monitoring for sensitive ingredients

RFID tracking for ingredient and batch identification

Smart dispensing systems for precise formulation

Video Resources

Play Video

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Play Video

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Play Video

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Play Video

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Frequently

Asked Question

Get answers to common questions about Personal Care Products Industry

Can eresource Bpro manage formulations and ingredient-level recipes?

Yes. It maintains detailed formulations, ingredient ratios, and batch scaling.

Does the ERP support hygiene control and GMP compliance?

Absolutely. Bpro includes hygiene workflows, GMP logs, and audit-ready documentation.

Can it track allergens and sensitive raw materials?

Yes. Allergen tagging, segregation, and traceability are fully supported.

Does the ERP manage QC activities like stability and microbial testing?

Yes. All QC and stability test records are captured digitally.

Can it handle filling, labeling, and packaging workflows?

Yes. Bpro tracks filling lines, packaging materials, and WIP at each stage.

Is Bpro suitable for multi-category personal care manufacturers?

Yes. It supports skincare, haircare, hygiene products, cosmetics, and more.

Transform Personal Care Manufacturing with eresource Bpro

Experience how eresource Bpro ERP strengthens formulation, production, quality, inventory, and financial workflows for the personal care industry.