The intricacies of the steel industry’s operations also change with time. An ERP system that has been properly deployed is a vital tool for everyone working in the steel industry to navigate the complex world of production and management. The difficulties of managing many business divisions may already be well known to you; in this situation, eresource Xcel ERP for the steel industry can help by redefining the information and activity flow throughout your company.

In every stage of your steel production process—from melting to finishing coat— running like clockwork under a single, all-encompassing system. This is where implementing eresource Xcel ERP system for the steel sector excels, significantly simplifying your business processes. It ensures that the entire process maintains high standards without sacrificing efficiency by blending production management and quality control in a seamless manner.

In order to succeed in the steel sector, companies must keep an eye on every aspect of its operations. eresource Xcel ERP software for the steel industry establishes a single, integrated platform where all departmental operations are visible. Each division properly complements the others by coordinating procurement with inventory levels, production with sales predictions, and shipments with client demands.

Highlights

Adopting a cutting-edge ERP for the steel sector gives you the power to integrate crucial tasks that drive your business toward long-term growth and profitability and dramatically streamline operations. This technology is your next step forward, whether your goal is to accomplish seamless business activity orchestration, tighten manufacturing timetables, or better material tracking.

Key advantages of eresource Xcel ERP for Steel Industry

The advantages of eresource Xcel ERP in the steel business can provide you the clarity to make an informed selection when you’re thinking about updating your operational infrastructure. This system for steel production of the highest caliber is essential for businesses aiming for operational excellence and performance improvement. Let’s examine the main benefits that eresource Xcel ERP system for steel businesses offer.

Streamlined Cross-Company Integration: This ERP system is excellent solution at breaking down departmental walls and creating a unified workplace where information and processes are easily shared throughout your whole business.

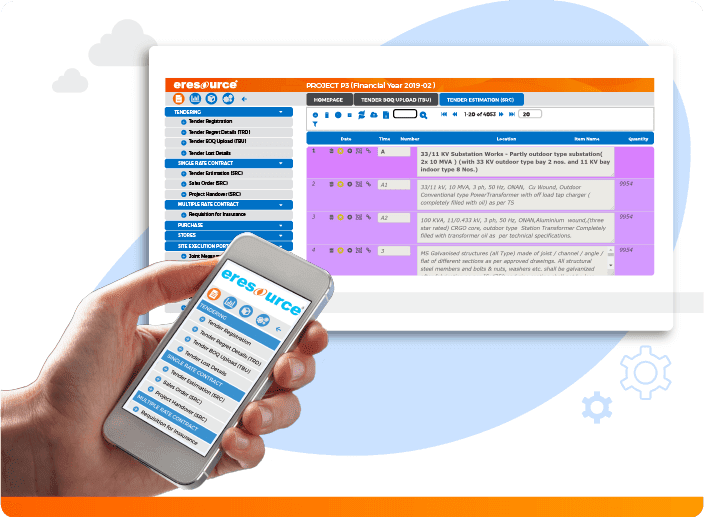

Simplified Planning and Costing: The system makes it easier to handle the complex aspects of planning and costing. Significant reductions in manufacturing and sales cycles are achieved by decomposing these intricate jobs.

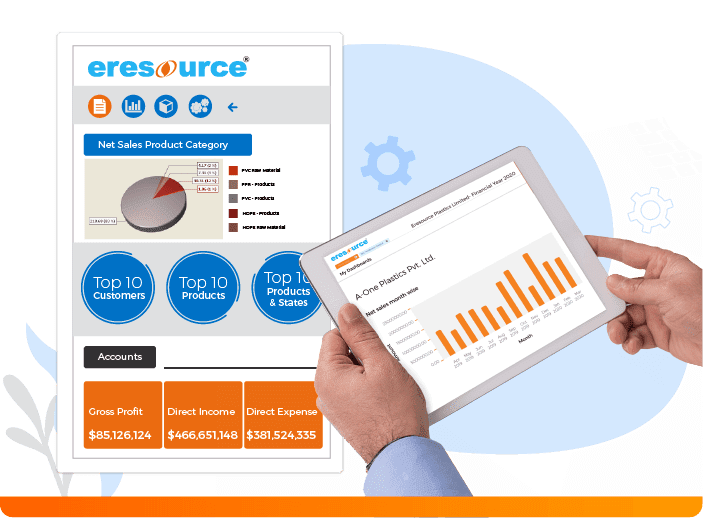

Detailed Process Overview: Get a bird’s-eye perspective of all the important data points and processes in your company. This is very helpful for accurate business analysis and decision making.

Improved Business Forecasting: Accurate forecasting is essential to preserving a competitive edge in fast-moving markets. eresource Xcel ERP gives you the strong oversight you need to predict and take confident action.

Expense management: The system makes it simpler to keep a close check on your expenses and guarantees that the quality of your deliverables and cost-efficiency are balanced.

Flexibility with Product Variations: Easily adjust to changing market conditions or customer requests for customisation. Variations in products can be accommodated by a superb ERP system without sacrificing workflow consistency or efficiency.

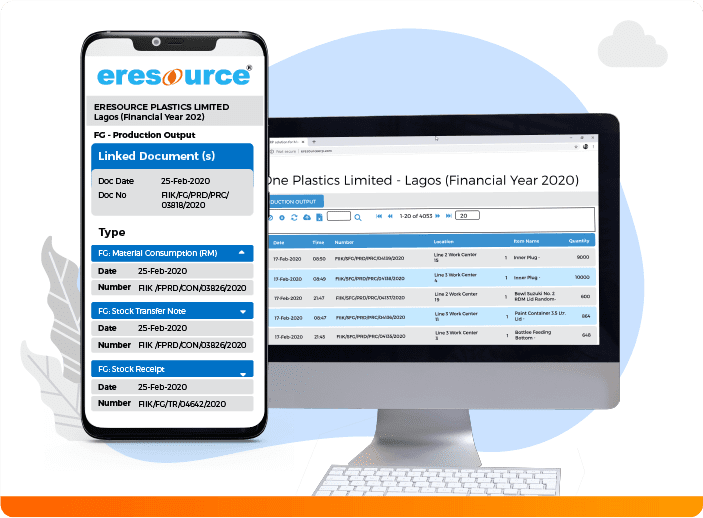

Better Inventory Tracking: Real-time tracking and analytics, which is a top feature in this ERP system, help minimize loss and optimize inventory levels.

A integrated web-based ERP software provides a degree of interoperability that was difficult and expensive to achieve with standalone, custom-built systems. eresource’s web-based ERP serves many industries and numerous functional areas in an integrated fashion and automate operations from supply chain management, inventory control, manufacturing scheduling and production, sales support, customer relationship management, financial and cost accounting, human resources and almost any other data-oriented management process.

With an ERP system like eresource, business operations have become much easier. For example, when a salesperson enters an order in the field, the transaction can immediately flow through to other functional areas both within and external to the firm. The order might trigger an immediate change in production plans, inventory stock levels or employees’ schedules, or lead to the automated generation of invoices and credit evaluations for the customer and purchase orders from suppliers.

Every growing organization must realize that ERP systems have become the most significant IT investment for most companies in their capital budgeting.

As far as any business is concerned, customer demand is by far the most influential factor. Manufacturing industry is one of the businesses that strive to make a nation grow with its contribution to the national economy. And a country that gives priority to its manufacturing sector could achieve success in its mission to bring the country into the mainstream of world business. India’s new initiative in this phase, ‘Made in India’, is moving in the right direction with many overseas companies are finding our nation as a fertile soil to manufacture their goods indigenously.

eresource, a purely indigenous Manufacturing ERP software, is contributing largely into the growth of manufacturing business by providing one of the excellent technology. When the automation becomes way of life no companies can keep away from this technological advantage. Understanding the need of every industry, eresource has come out with industry specific ERP system for every industry verticals and ‘eresource Xcel’ is an exclusive ERP for manufacturing industry. eresource Xcel, a viable ERP system that has been integrated with all essential modules for manufacturing industry.

Following are some of the prime advantages of eresource Xcel,