eresource Xcel is an ERP tool that identifies and optimizes every areas of your manufacturing business to cope with the best industry practice.

For manufacturing business the time frame is very important. The raw materials must reach on time in production plant so that it will enable the product to be delivered on time as per the market demand.

eresource ERP system makes all your business operations self-reliant and depending on a third party company to solve any problem never arises.

It is very time consuming to work with an outdated software application for your business operations. Implement the hi-tech next-gen ERP solution as your business solution.

Businesses need an integrated working system with centralized data management. Scattered software applications are not only waste of money but could severely bring business setback.

Poor quality of products can only help lose valuable customers and market share. Especially pertaining to the quality of a ‘safety critical’ product, any defect could be catastrophic and costly.

Are you benefiting from the full-potential of your people? A committed and motivated workforce can do wonders in your business. Make them ready to win the battle with an efficient business tool.

All manufacturing industries go through diverse processes and manufacturing operations to produce the final products that are required to meet the market requirements. From procurement of raw materials to a product of final material to the market all the operational procedures must be carried out within a scheduled time frame.

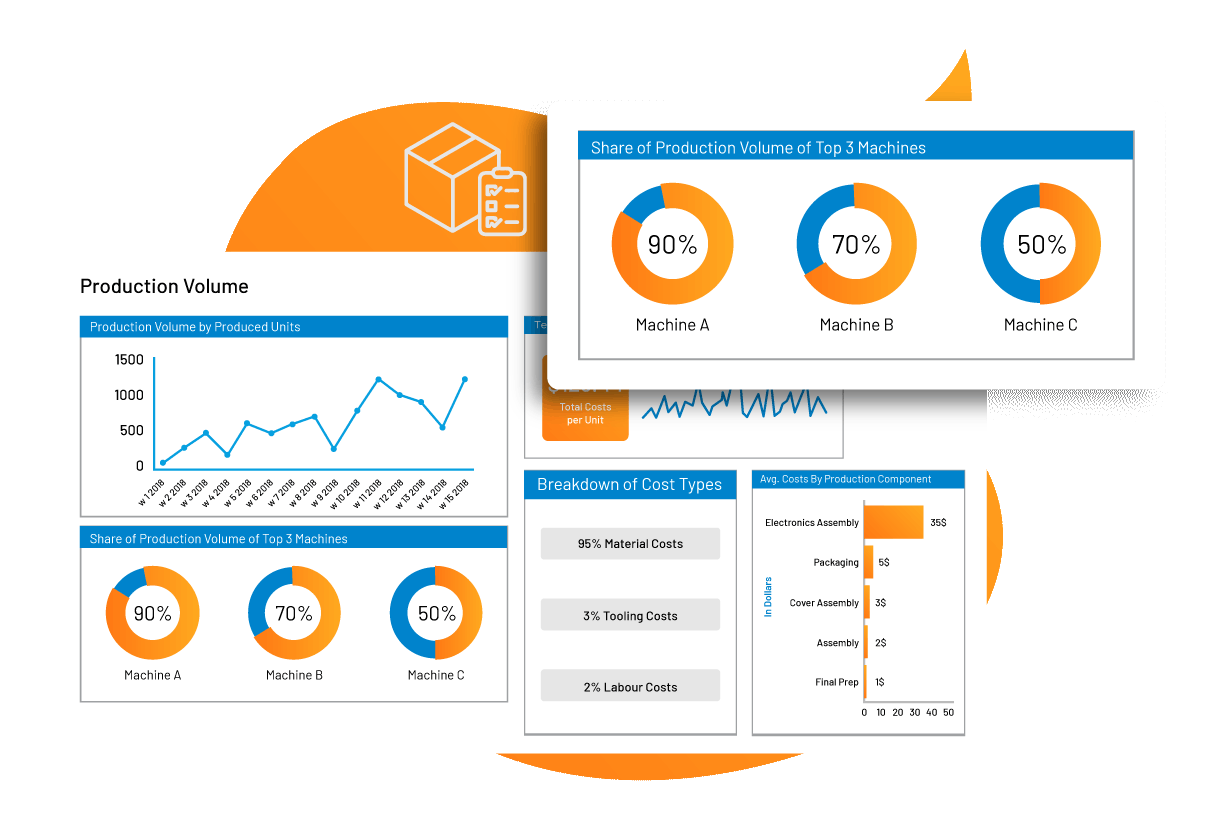

A successful series of manufacturing processes ensures control of operations and enables to maintenance time schedules. However, to manage these operations in this specified manner manufacturing companies have to deploy a suitable and efficient enterprise solution. High-tech ERP systems for the Manufacturing Industry like eresource Xcel can help this operation run smoothly and successfully.

Manufacturing business is a vast sector with some categories under Discrete Manufacturing, Process Manufacturing, and Lean Manufacturing. Steel Manufacturing, Plastic Manufacturing, and Rubber Manufacturing fall under the first category of Discrete Manufacturing. There are Pharmaceuticals and Chemicals and Food Processes etc come under the process manufacturing category. The highlight of eresource ERP system is that it has developed an exclusive system for all these industries, making all manufacturing operations easy, quick, and efficient.

In this era of high-tech solutions, standalone applications have become history. ERP solutions with useful modules integrated intelligently are essential to manage any manufacturing business successfully.

eresource Xcel provides the manufacturing industry with an ERP system to tackle challenges. This comprehensive ERP system addresses every area of the manufacturing process. eresource Xcel ERP for the manufacturing industry is a robust ERP software to accommodate all the needs of its clients. eresource Xcel ERP has been developed to meet the modern standards of manufacturing business, focusing on the core needs of the manufacturing processes and operations.

Key Benefits of ERP for Manufacturing Industry

Key Modules of ERP for the Manufacturing Industry

Key Features of ERP for the Manufacturing Industry

Types of Manufacturing Industries

There are a number of manufacturing industries that are doing business around the world. Anything that you see in front of you is a product of a manufacturing process. However, we name here some manufacturing industries for your reference.

♦ Steel Manufacturing Industry

The steel manufacturing industry is one of the economy-driving industries. The steel industry supports a plethora of other industries like automobile, infrastructure, Steel TMT bar, defense, and railways. Manufacturing ERP software helps the industry run and function.

♦ Plastic Manufacturing Industry

The Plastic Manufacturing Industry is one of the major industries that contribute largely to the economic situation of a country. Therefore the stability and growth of this industry cannot be downplayed. Hence having a suitable enterprise solution to manage the business can’t be neglected.

♦ Pharmaceutical Industry

The pharmaceutical industry deals in supplying cures and medicines to the entire world. Every medicine contains a specific amount of chemical composition, and it must be precise to avoid series repercussions. To avoid such difficulties, the Pharmaceutical industry opts for ERP software to ease the process.

♦ Fast Moving Consumer Goods (FMCG) Industry

As we said earlier, there is anything that used by you now has gone through some manufacturing process. From the table your computer is placed, the computer you use, the chair you sit on, the pen you write in, the teacup that you had your tea all and everything is the result of a manufacturing process. It is therefore, the supply and demand chain in the FMCG industry is continuously busy, hence FMCG industry has to deploy an efficient and effective ERP solution to manage all their business process.

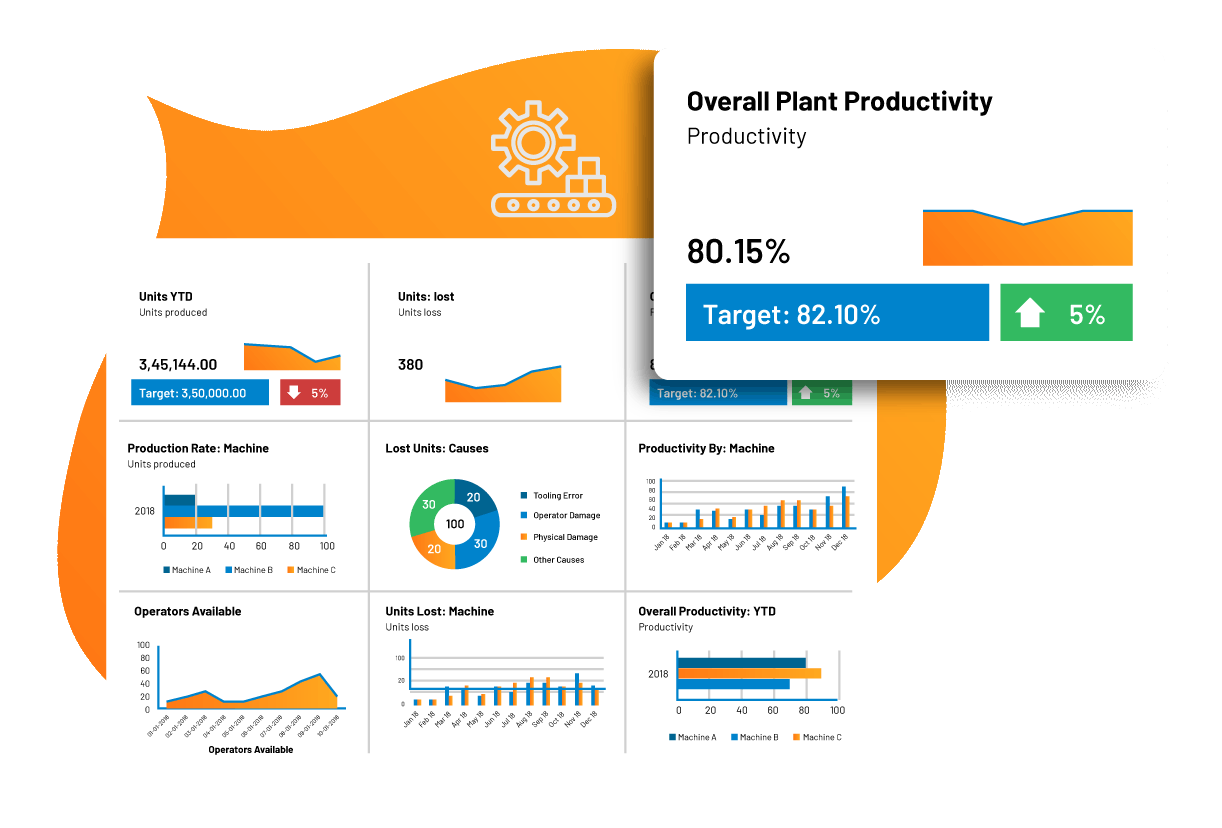

This easily customizable ERP system will go well with one and all. eresource Xcel ERP system enables manufacturers to track all supply chain movement. Remedial measures can be taken to guarantee smooth stream of manufacturing activities by identifying processes that can create disruption in production. An Integrated Planning and Shop Floor Production Function with sales orders, inventory, purchasing and Supplier Management, accounting, and financial reporting play an important role to provide real-time coordination across all verticals of yo... Read More

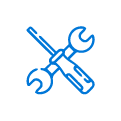

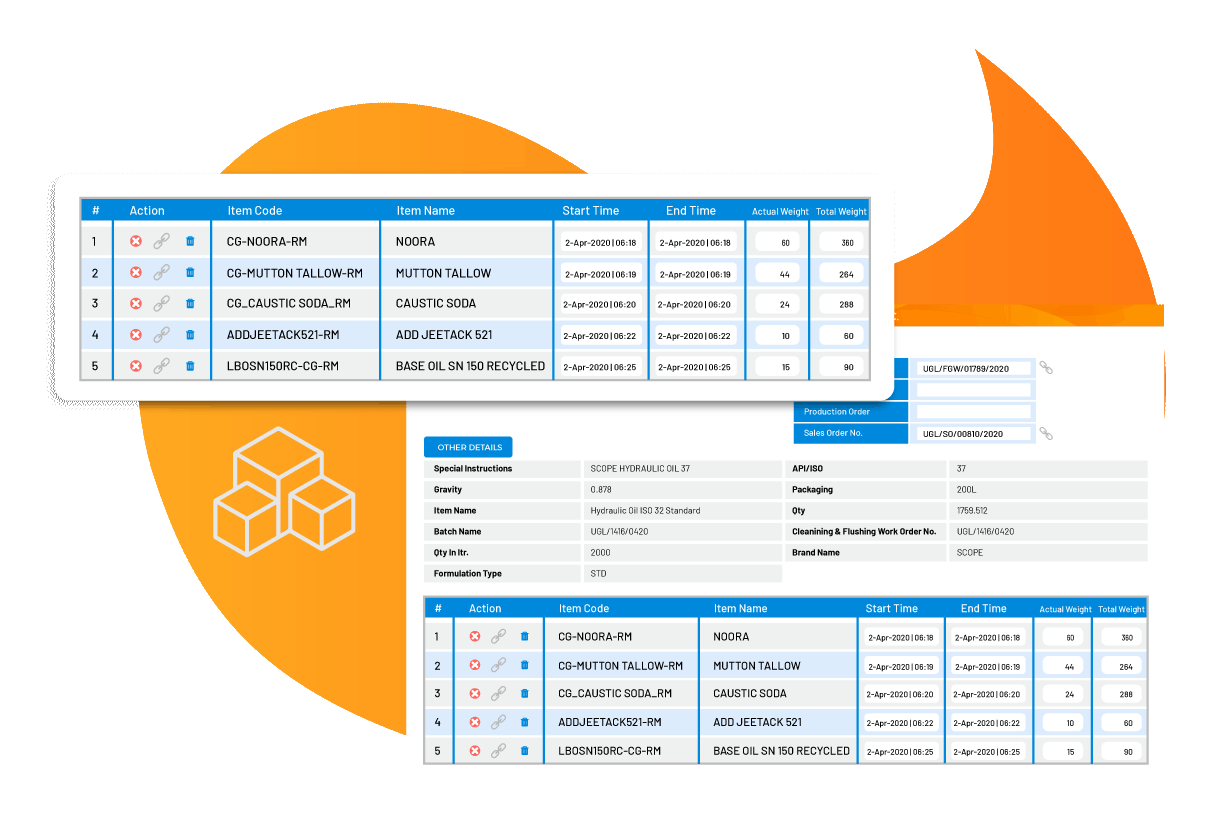

eresource Production and Shopfloor module controls the movement of materials during the production process. Production is managed through the use of production orders. These orders indicate the qua... Read More

Master Planning Scheduling (MPS) provides a master plan for what you need to produce, how much to produce, and when to produce it, based upon one’s supply and demand. eresource MPS module provide... Read More

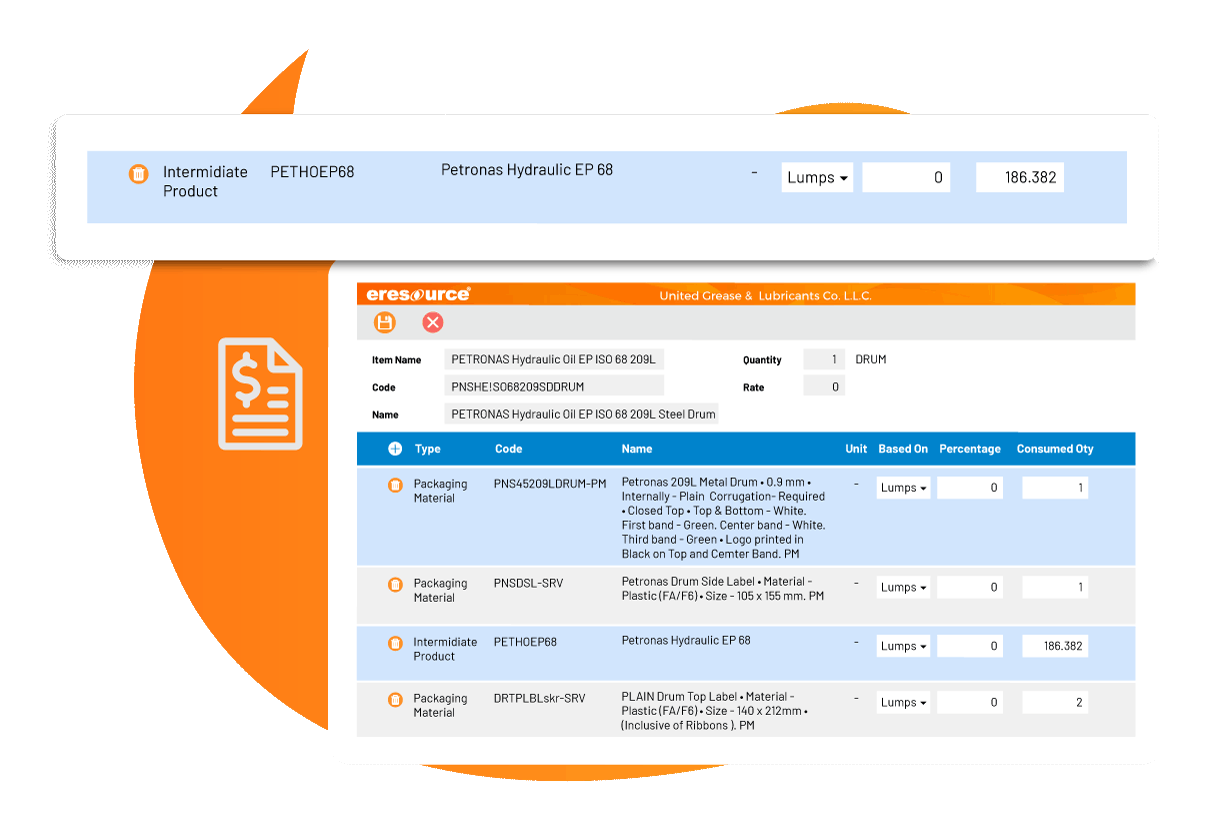

A BOM in eresource can be defined in a hierarchy manner with list of Raw Material, Parts, Components, Assemblies and Sub-Assemblies needed to make one unit of the Product. A BOM is tightly integrat... Read More

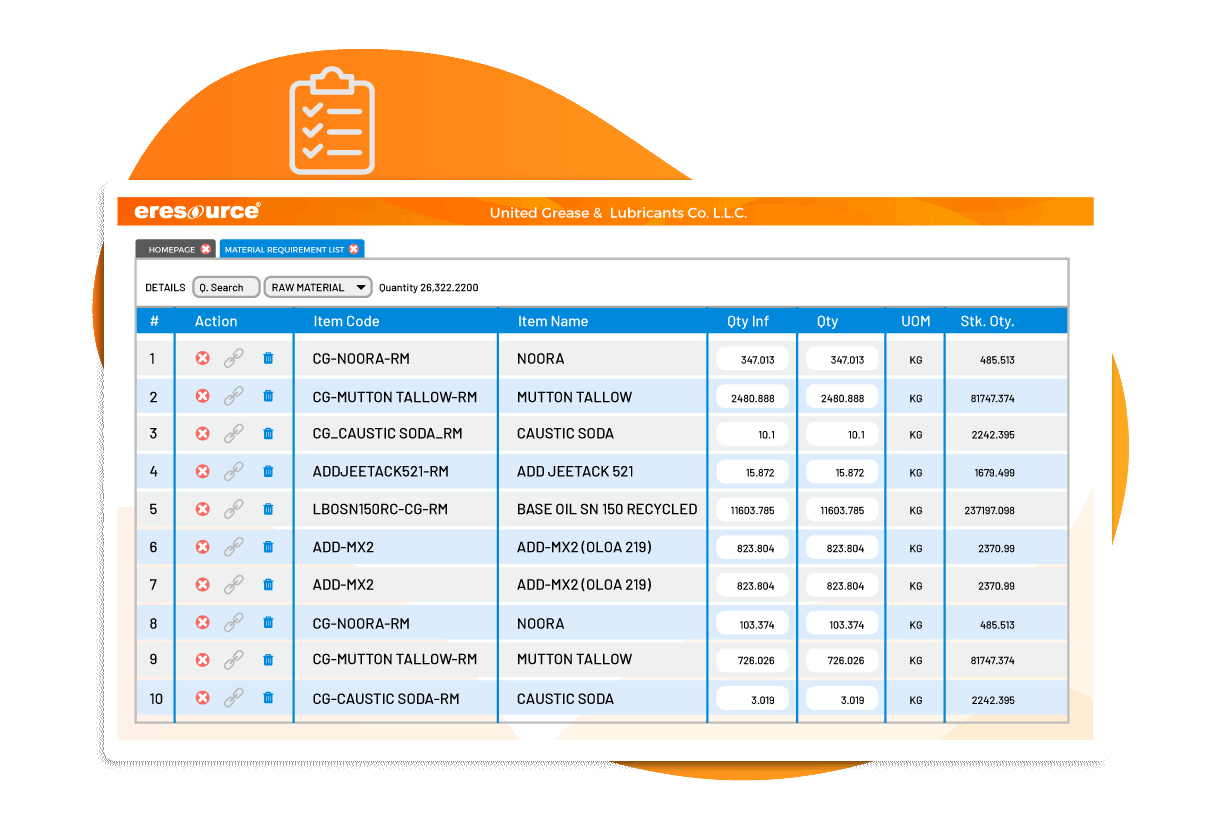

The eresource Material Requirement Planning (MRP) function is used to procure or the required material quantities on time for the purpose of Production. The MRP can be generated against the Master... Read More

In Eresource, Production of Semi-Finished Goods or Finished goods is managed through production orders. Production order can be created against the Master production schedule or directly against th... Read More

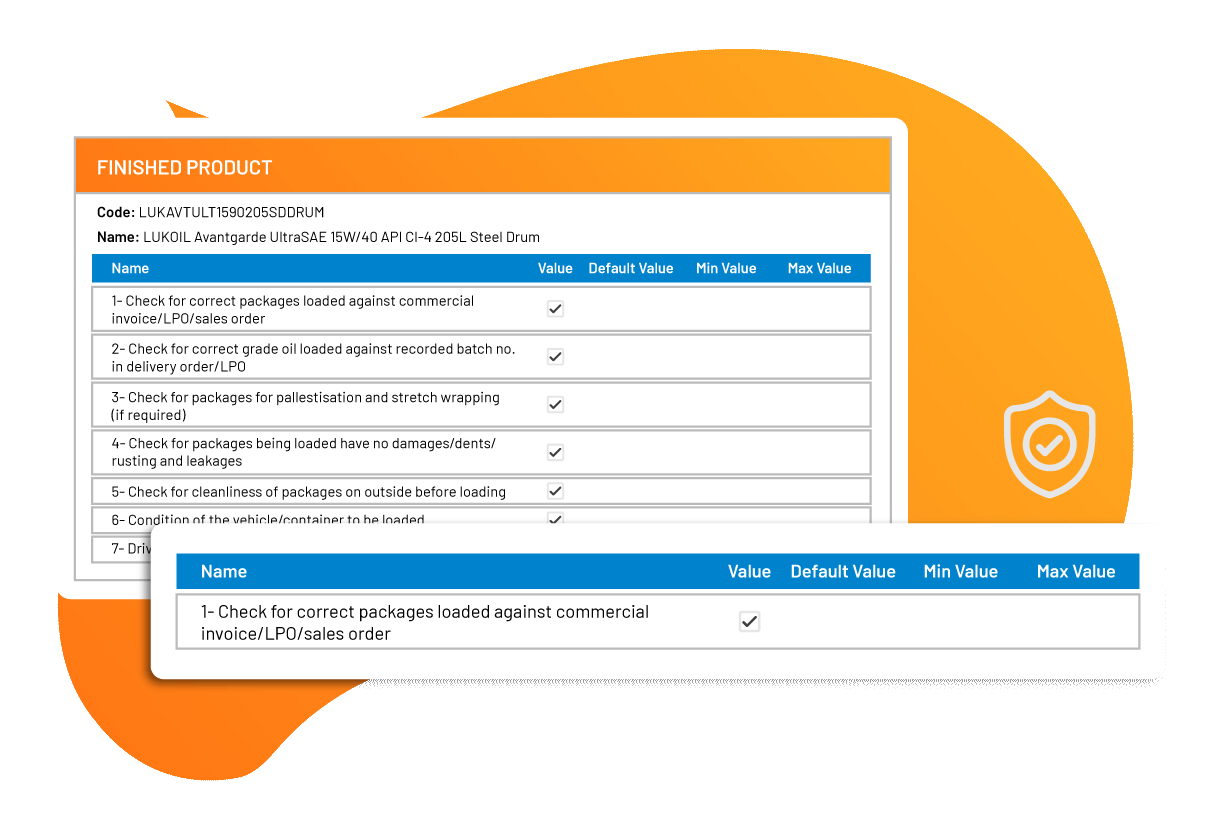

The Quality Management module in eresource fulfils following functions.

Quality planning, Quality Check Definition, Quality Characteristics for different type of quality check (likewise, Inwa...

Read More

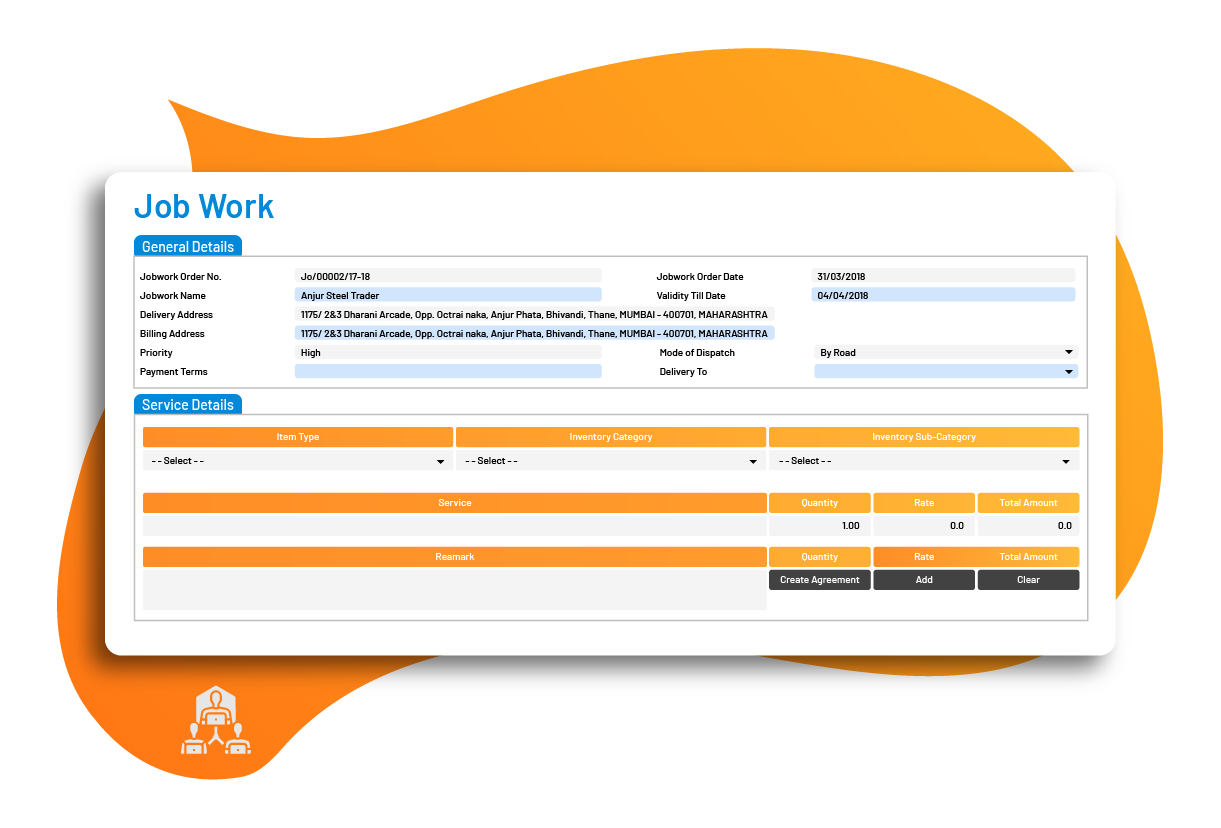

Jobwork module in eresource is used to product any semi-finished goods or finish goods or any manufacturing activity to other workers outside the company to get the job done. Jobwork Management mod... Read More

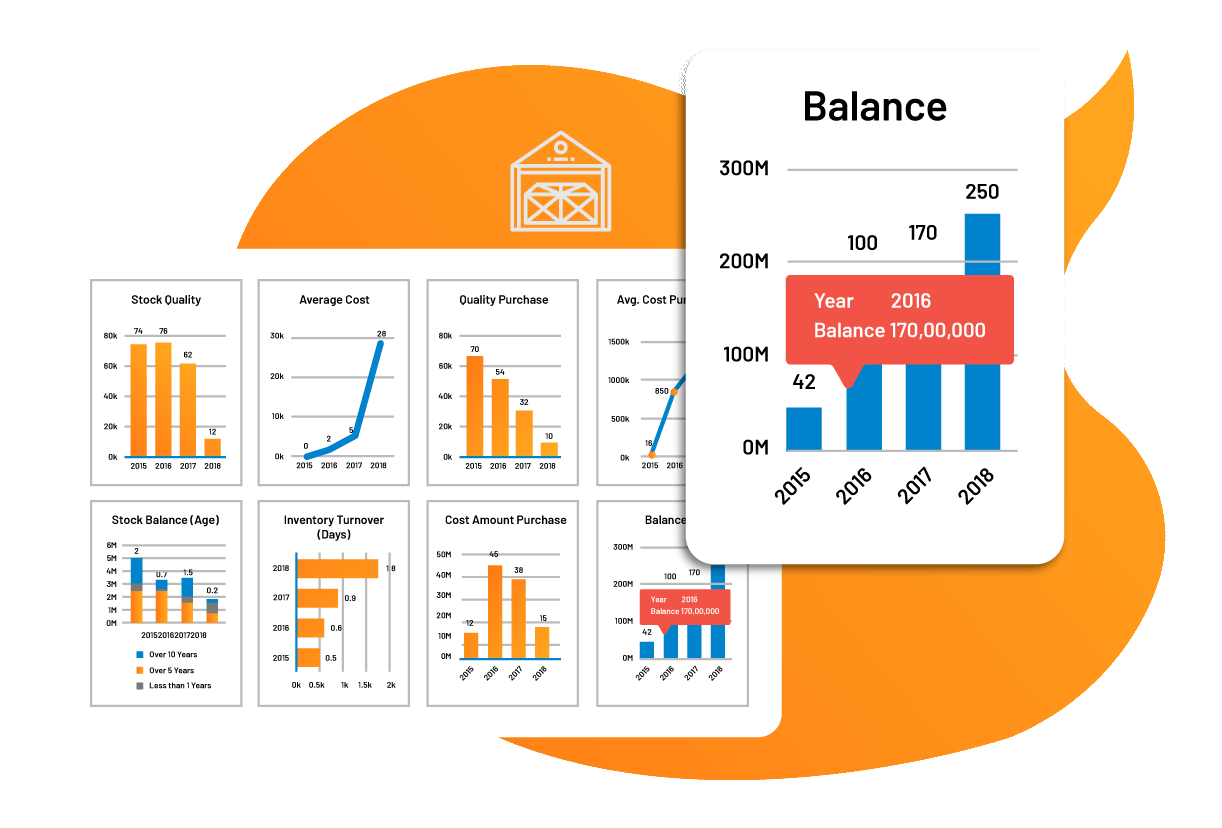

The stores and inventory management module automates material Requirement process. Inventory Management module comprises of functions like Receipt of goods, Quality Check, Delivery of Goods, Stock ... Read More

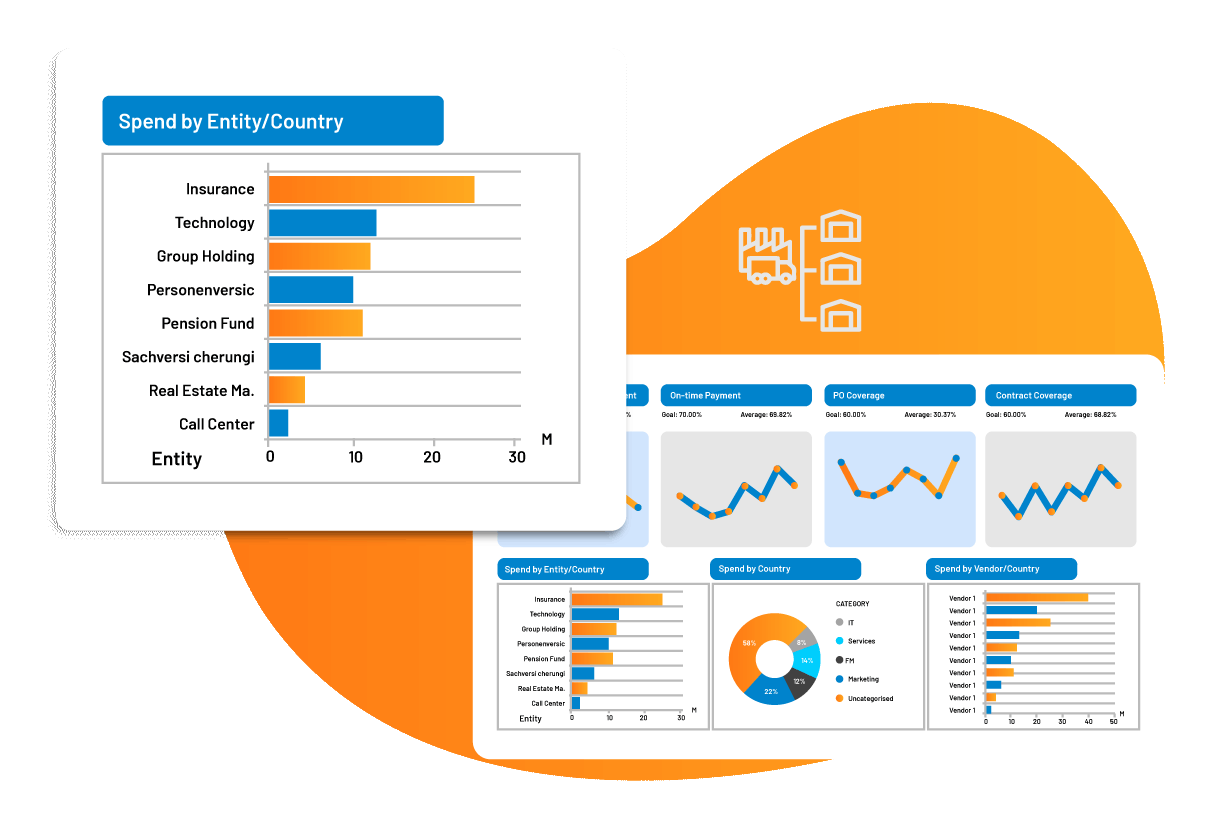

Purchase Module in Resource helps organizations maintain masters for various suppliers and their contacts, track purchases, get a complete purchase rate history etc. The module systematically recor... Read More

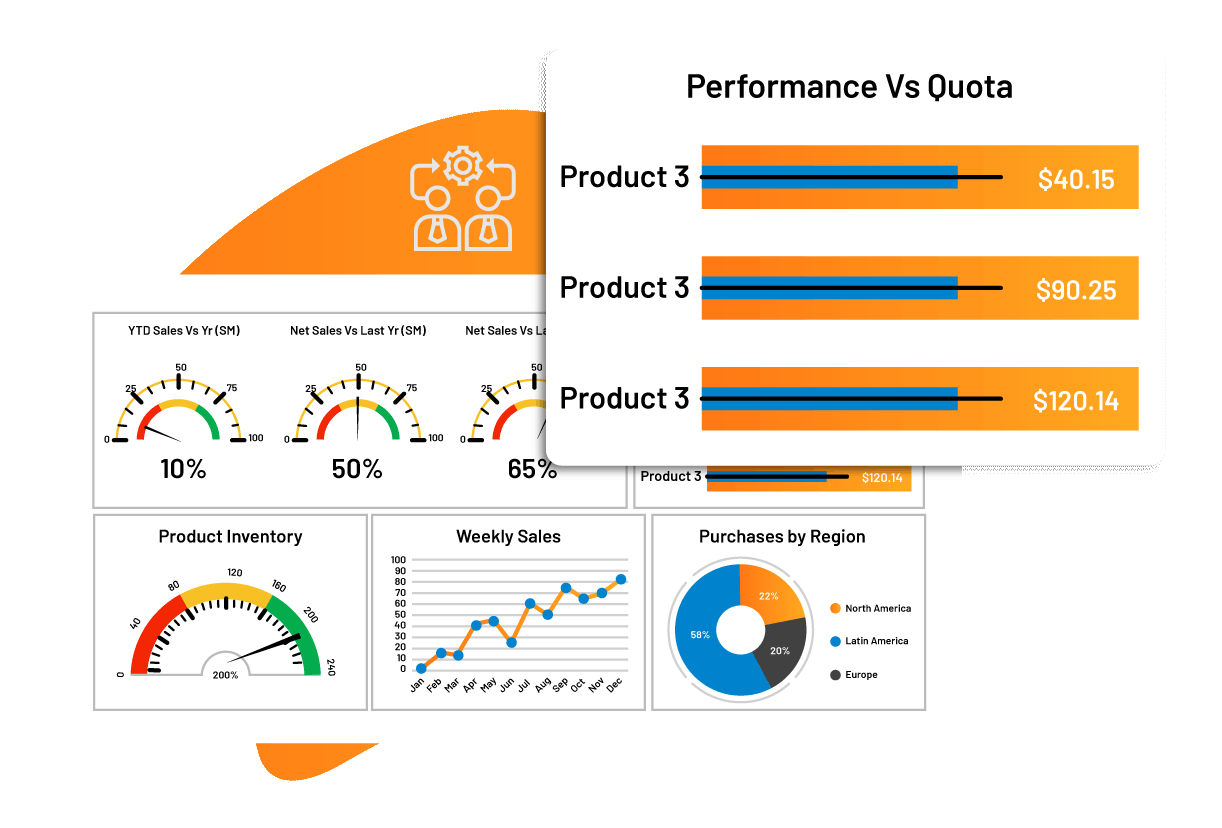

A powerful CRM module in Resource Business Management solution helps enterprises to generate, Sales Lead, Maintain Customer Masters and Product Price List, Process incoming enquiries, send out quot... Read More

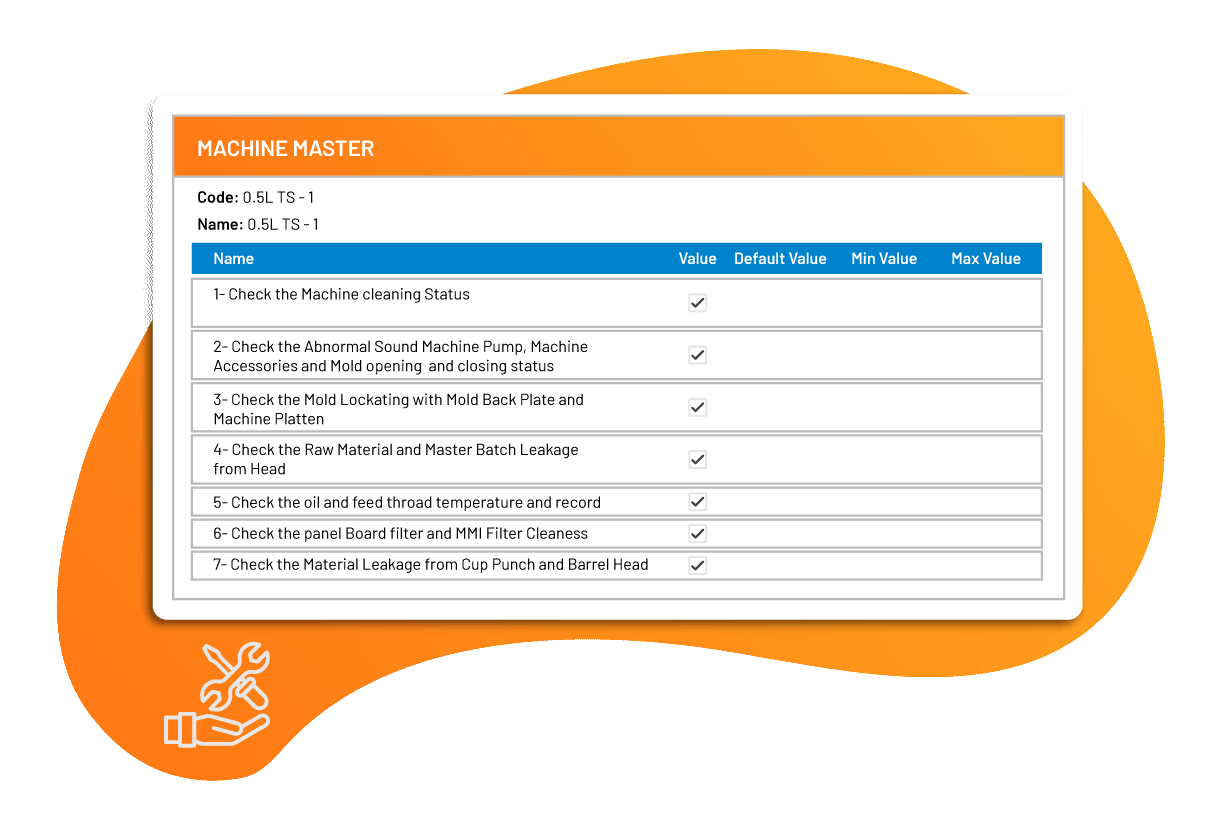

Plant Maintenance is critical part of Manufacturing Operations Management. The functions of plant maintenance in eresource helps achieve minimum breakdown and keep the plant in good working cond... Read More

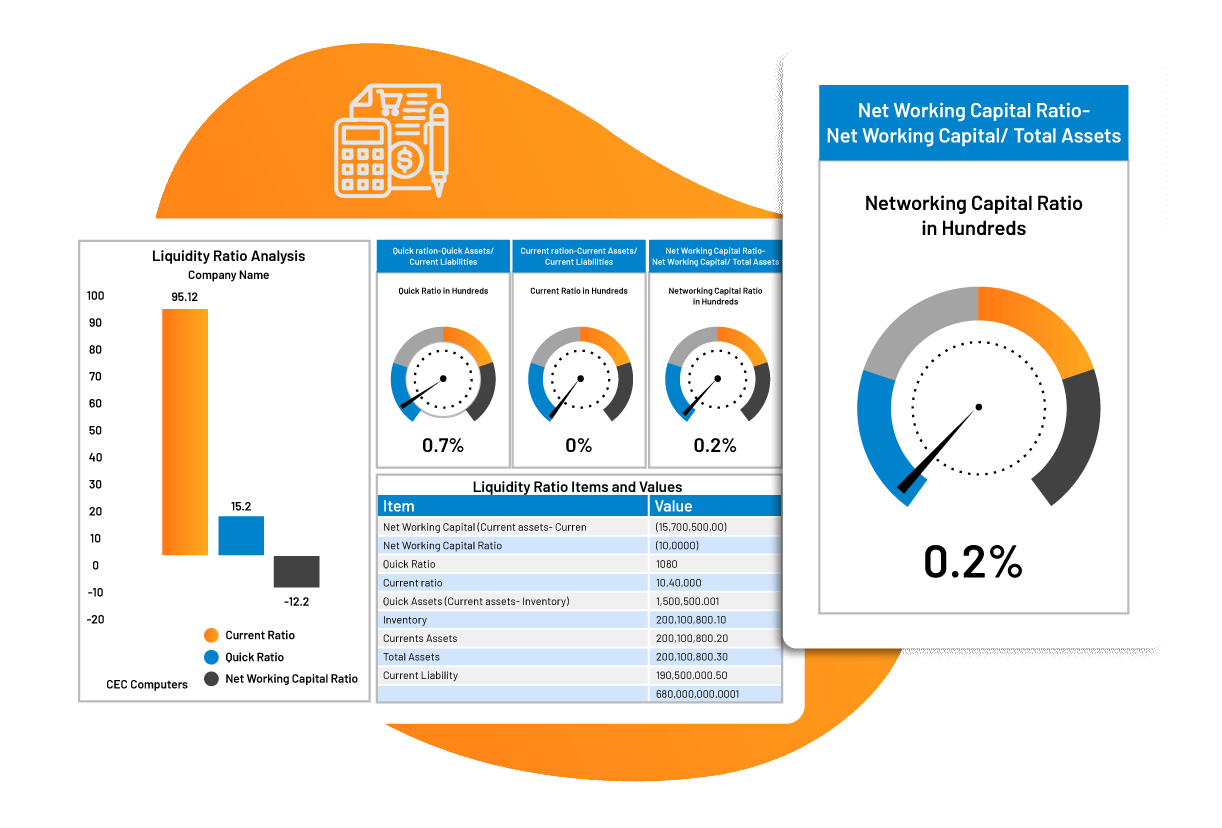

eresource, is primed with a reliable Finance and Accounting module with powerful and all-encompassing financial management functions. This module would enable you to efficiently manage your finance... Read More

There are over 3000 Manufacturing companies using eresource Xcel ERP and that includes, Make To Order, Make to Stock, Engineer to Order, Assemble to Order and Mix Mode Manufacturing companies. We also exclusive ERP for Process Manufacturing or batch manufacturing practice, We call that product as “BPro ERP”.

These are accounting solution with inventory and sales order processing. These solution are good for small Trading companies. But if you are in Manufacturing, contracting or service industry, you would need a exclusive ERP product which is designed exclusively for your business. For example, Manufacturing ERP comprises of very comprehensive Production and Shop floor operation, capacity and Demand management, Planning and Material management, Supply Chain Management, Customer Relationship, Fixed Asset and Accounts and Finance Management. If you need visibility of all strategic information across all your departments and divisions on-time so that you can take decision faster, yes, then, you need to switch over.

eresource is the only ERP system that is 100% scalable, flexible and adaps to different business dynamics with any programming efforts. It is ZERO coding ERP product. The entire ERP is evolved out our inhouse framework. Becuae there is no programing the deployment becomes extremely fast. Even after the deployment if the customer may require any changes, the lead time for any change is not more then an hour. I cannot miss to tell you, Migration of data is possible in just few clicks. Maximum time to Implement any ERP is 25 working days.

There is no customization in eresource ERP. Any changes/alteration is 100% configurable.

A integrated web-based ERP software provides a degree of interoperability that was difficult and expensive to achieve with standalone, custom-built systems. eresource’s web-based ERP serves many industries and numerous functional areas in an integrated fashion and automate operations from supply chain management, inventory control, manufacturing scheduling and production, sales support, customer relationship management, financial and cost accounting, human resources and almost any other data-oriented management process.

With an ERP system like eresource, business operations have become much easier. For example, when a salesperson enters an order in the field, the transaction can immediately flow through to other functional areas both within and external to the firm. The order might trigger an immediate change in production plans, inventory stock levels or employees’ schedules, or lead to the automated generation of invoices and credit evaluations for the customer and purchase orders from suppliers.

Every growing organization must realize that ERP systems have become the most significant IT investment for most companies in their capital budgeting.

A integrated web-based ERP software provides a degree of interoperability that was difficult and expensive to achieve with standalone, custom-built systems. eresource’s web-based ERP serves many industries and numerous functional areas in an integrated fashion and automate operations from supply chain management, inventory control, manufacturing scheduling and production, sales support, customer relationship management, financial and cost accounting, human resources and almost any other data-oriented management process.

With an ERP system like eresource, business operations have become much easier. For example, when a salesperson enters an order in the field, the transaction can immediately flow through to other functional areas both within and external to the firm. The order might trigger an immediate change in production plans, inventory stock levels or employees’ schedules, or lead to the automated generation of invoices and credit evaluations for the customer and purchase orders from suppliers.

Every growing organization must realize that ERP systems have become the most significant IT investment for most companies in their capital budgeting.

As far as any business is concerned, customer demand is by far the most influential factor. Manufacturing industry is one of the businesses that strive to make a nation grow with its contribution to the national economy. And a country that gives priority to its manufacturing sector could achieve success in its mission to bring the country into the mainstream of world business. India’s new initiative in this phase, ‘Made in India’, is moving in the right direction with many overseas companies are finding our nation as a fertile soil to manufacture their goods indigenously.

eresource, a purely indigenous Manufacturing ERP software, is contributing largely into the growth of manufacturing business by providing one of the excellent technology. When the automation becomes way of life no companies can keep away from this technological advantage. Understanding the need of every industry, eresource has come out with industry specific ERP system for every industry verticals and ‘eresource Xcel’ is an exclusive ERP system developed for manufacturing industry. eresource Xcel, a viable ERP system that has been integrated with all essential modules for manufacturing industry.

• eresouce Xcel is an ERP solution for manufacturing businesses through a variety of modules. Following are some of its modules and its functions:

• CRM module: Maintains a data of customer history.

• BOM module: Helps in maintaining product requirement details

• MPS module: Generates a detailed list of orders and required purchases

• Enterprise resource planning: Inventory management for the business

• Quality control module: Provides support from start till delivery.

• Job work management: Creates an easier way to manage outsourced work

• Finance resource management: accumulates all the financial information of all functional departments

• Production management: streamlines the manufacturing processes.

• Human Capital Management module: Manages the human resources of the business

Following are some of the prime advantages of eresource Xcel,

Eresource provides Manufacturing ERP Software in all Countries including India, USA, Africa, United Kingdom, UAE, Nigeria, Ghana, Canada, Oman, Uganda etc

Eresource provides Manufacturing ERP Software in all major cities of India, including Hyderabad, Delhi, Mumbai, Kolkata, Chennai, Coimbatore, Bengaluru, Pune, Chandigarh, Lucknow, Vijayawada, Visakhapatnam, Jaipur, Mysore, Gurugram, Patna, Noida, Surat, Dehradun, Nagpur, Allahabad, Bhopal, Ahmedabad, Indore, Kanpur, Vadodara, Navi Mumbai, Thane and Pondicherry etc.