Modules

-

Sales Management

A powerful CRM module in Resource Business Management solution helps enterprises to generate, Sales Lead, Maintain Customer Masters and Product Price List, Process incoming enquiries, send out quot... Read More

Key Features

- Sales Lead

- Sales Enquiry

- Sales Quotation

- Direct Sales Quotation

- Sales Order via Quotation

- Direct Sales Order

- Sales Scheduling

- Sales Order Cancellation

- Sales Order based Proforma Invoice

- Sales Order Short Close

-

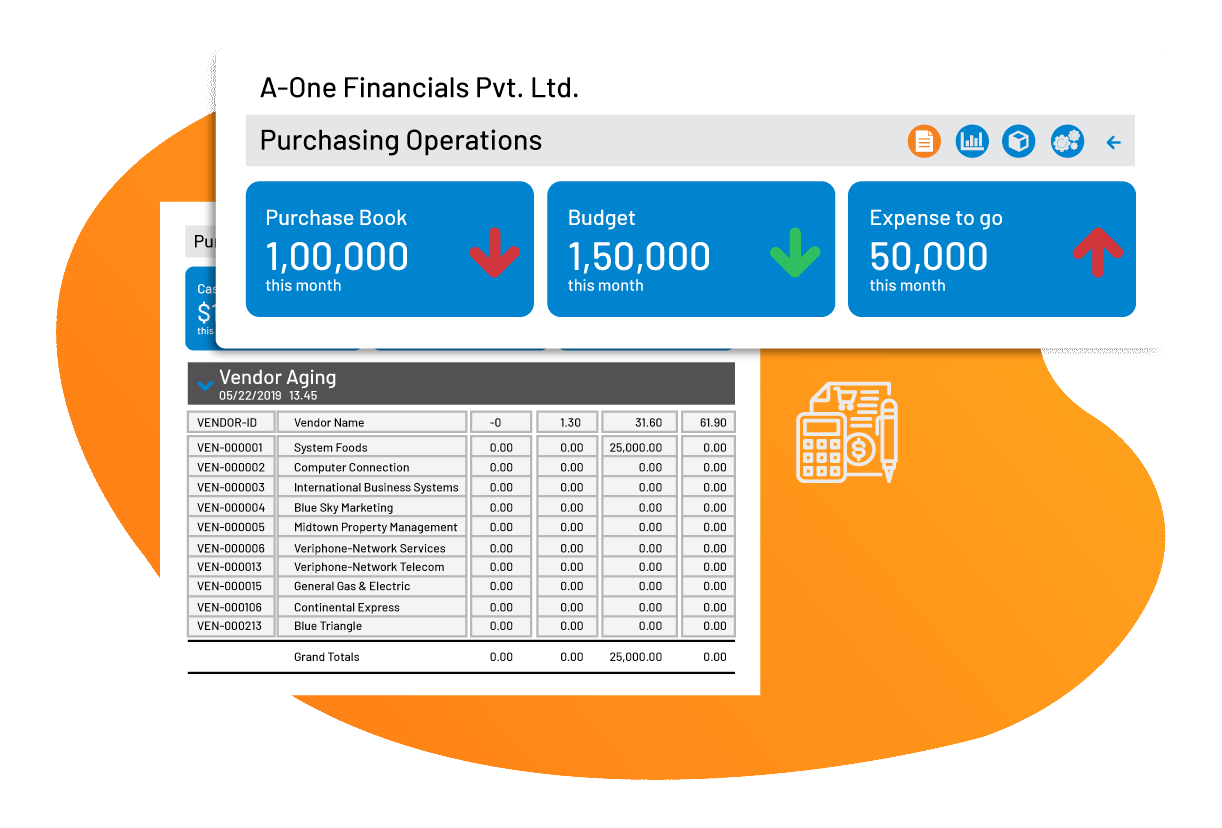

Supplier & Purchase Management

Purchase Module in Resource helps organizations maintain masters for various suppliers and their contacts, track purchases, get a complete purchase rate history etc. The module systematically recor... Read More

Key Features

- Direct Purchase Enquiry

- Purchase Enquiry Via Indent

- Purchase Quotation via Enquiry

- Purchase Order via Enquiry

- Quotation Comparison

- Purchase Order Via Indent

- Direct Purchase Order

- Purchase Scheduling

- Purchase Oder Cancellation

- Purchase Order Short Close

- Direct Service PO

- Purchase Invoice

-

Stores & Inventory Management

The stores & inventory management module automates material Requirement process. Inventory Management module comprises of functions like Receipt of goods, Quality Check, Delivery of Goods, Stoc... Read More

Key Features

- Stock Details

- Stock Reconciliation

- Vehicle In/Out Entry

- Material Requisition

- BOM Base Requisition

- Goods Receipt Note

- Material Issue

- Direct Sales Return

- Internal Return

- Material Rejection

- Miscellaneous GRN

- Traceability Generation

-

Bill of Material Management

A BOM in eresource can be defined in a hierarchy manner with list of Raw Material, Parts, Components, Assemblies and Sub-Assemblies needed to make one unit of the Product. A BOM is tightly integrat... Read More

Key Features

- Bill of Material

- BOM Tree Report

- BOM Print

- BOM Tree Stock Details Report

-

Production Order Management

In Eresource, Production of Semi-Finished Goods or Finished goods is managed through production orders. Production order can be created against the Master production schedule or directly against th... Read More

Key Features

- Production Job Card

- Process Wise Production Output

- Scrap Details

- Process Master

- Process Characteristics

- Machine Process Relation Setup

-

Master Production Scheduling Management

Master Planning Scheduling (MPS) provides a master plan for what you need to produce, how much to produce, and when to produce it, based upon one’s supply and demand. Eresource MPS module provide... Read More

Key Features

- Master Production Schedule (MPS)

- MPS Sub MFG Order

- Dereserve MPS Reserve

- Reallocation to Stock

- Reallocation to Other

- Rejection

-

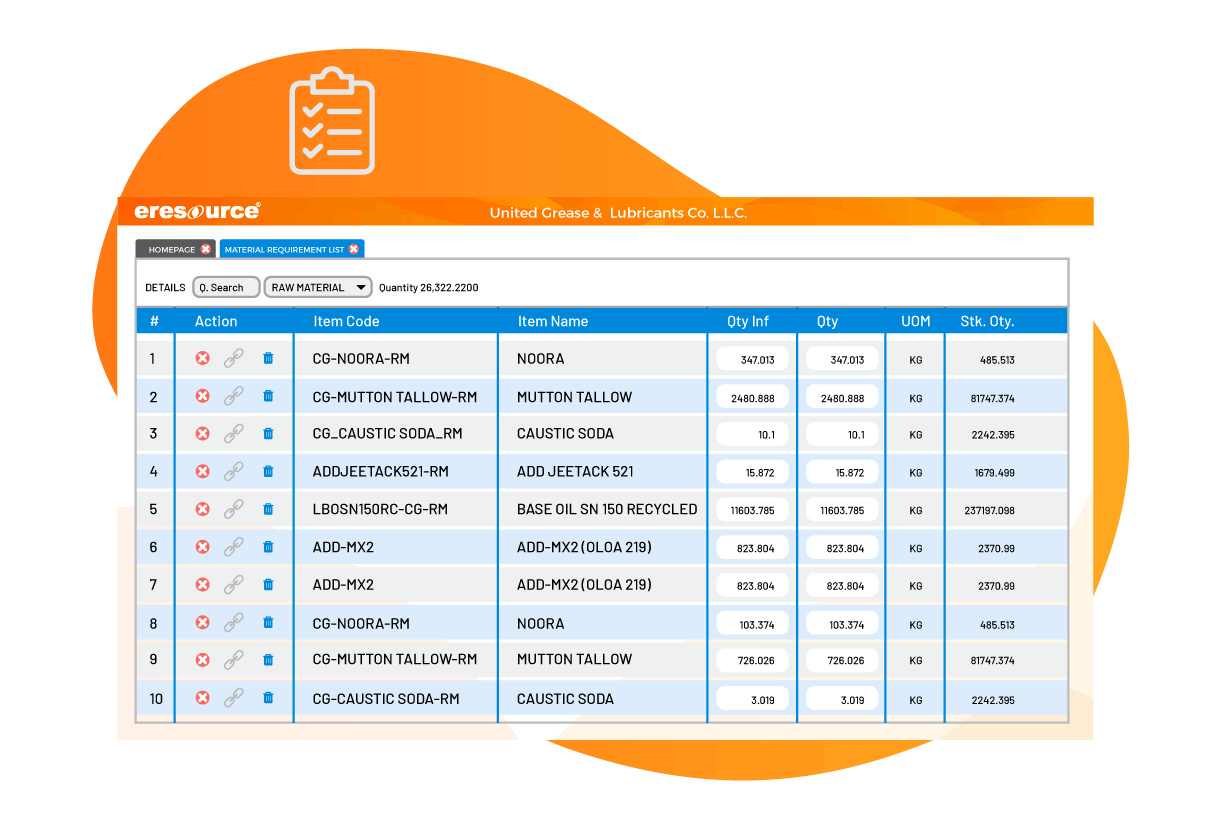

Material Requirement Planning

The eresource Material Requirement Planning (MRP) function is used to procure or the required material quantities on time for the purpose of Production. The MRP can be generated against the Master... Read More

Key Features

- Material Requirements Planning (MRP) Against MPS

- Dereserve MRP Reserve

- MRP Against Dereserve – Rejection

- Dereserve Indent Before GRN (MRP)

- Dereserve Indent After GRN (MRP)

-

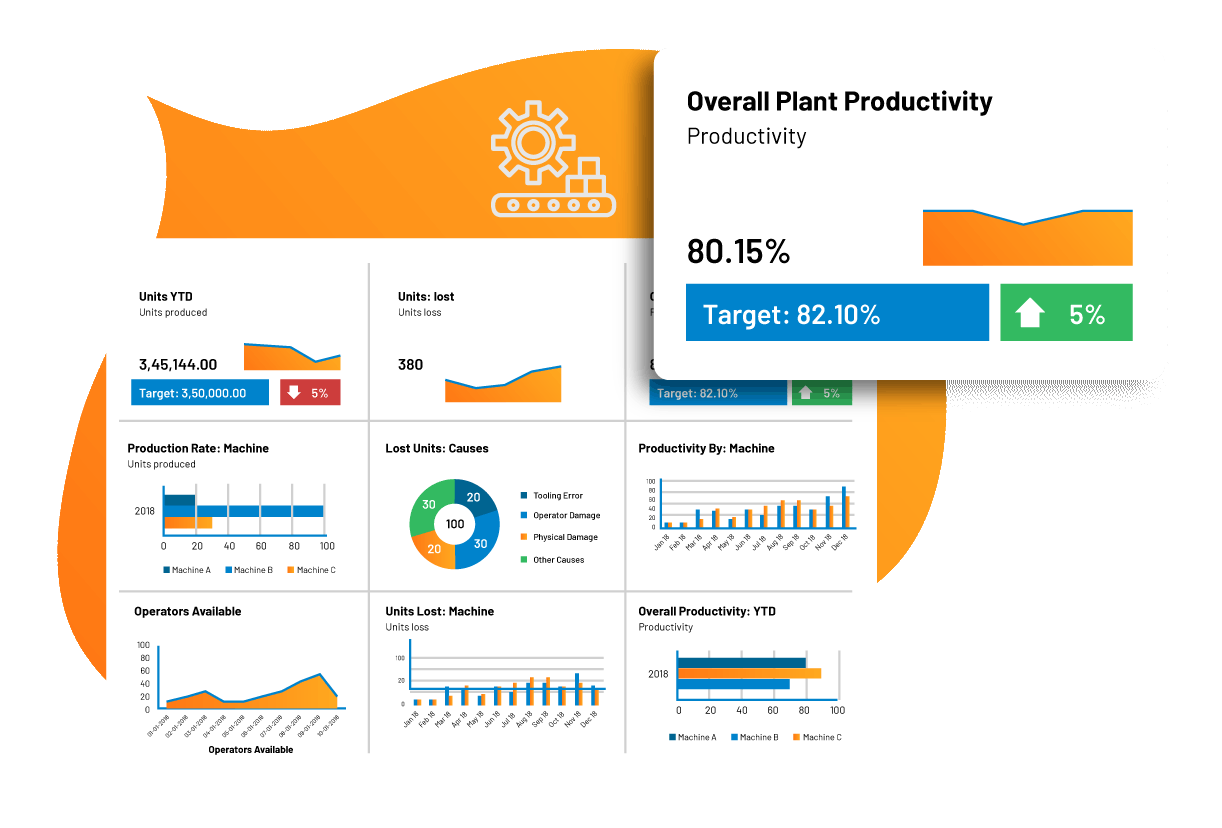

Production & Shop Floor Management

eresource Production & Shop floor module controls the movement of materials during the production process. Production is managed through the use of production orders. These orders indicate the ... Read More

Key Features

- Production Job Card

- Machine Process Relation Setup

- Item Machine Relation

- Item Process Machine Relation

- Item Wise Process Group Creation

- Stock Details

-

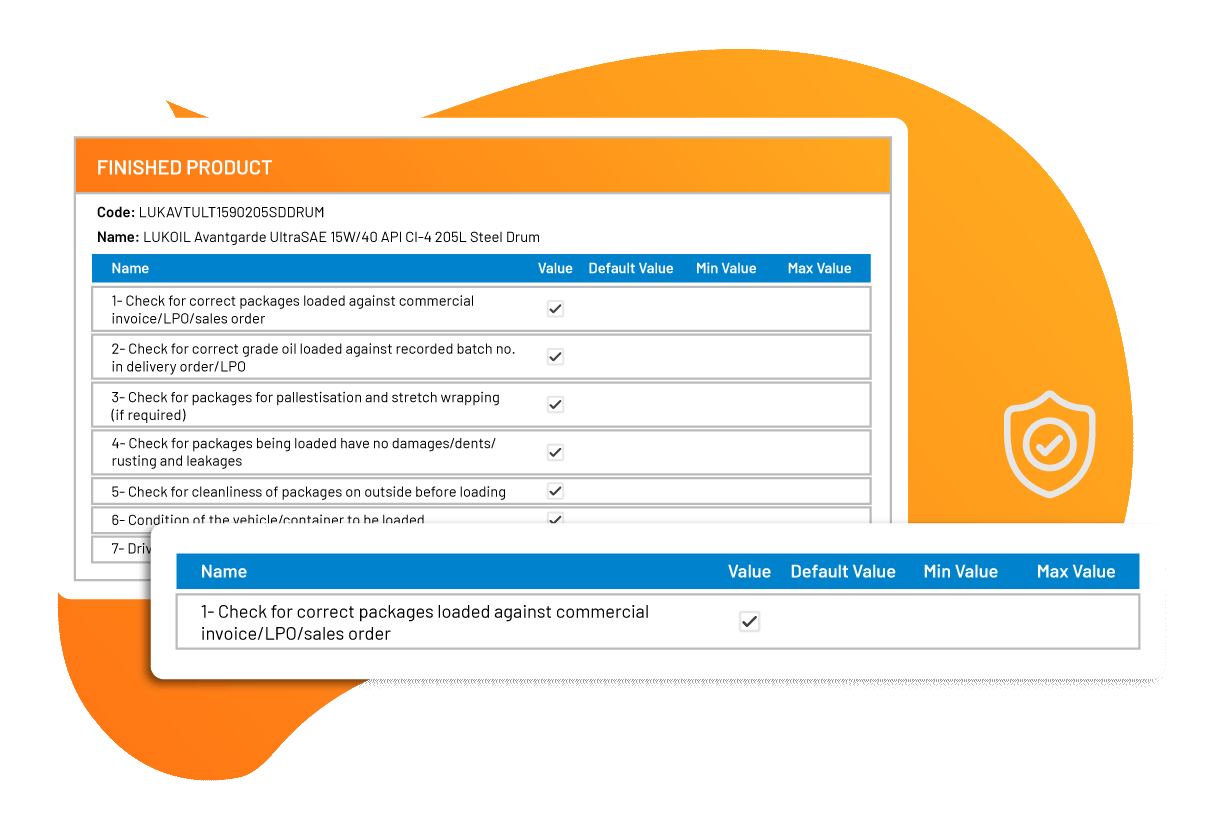

Quality Management

The Quality Management module in eresource fulfils following functions.

Quality planning, Quality Check Definition, Quality Characteristics for different type of quality check (likewise, Inwa... Read MoreKey Features

- QC Characteristics

- QC Test Parameter Relation

- Inward QC

- In-Process QC

- FG Quality Management

- Item Test Relation

- Item Wise QC Characteristics

- Item Wise Test Parameter Relation

-

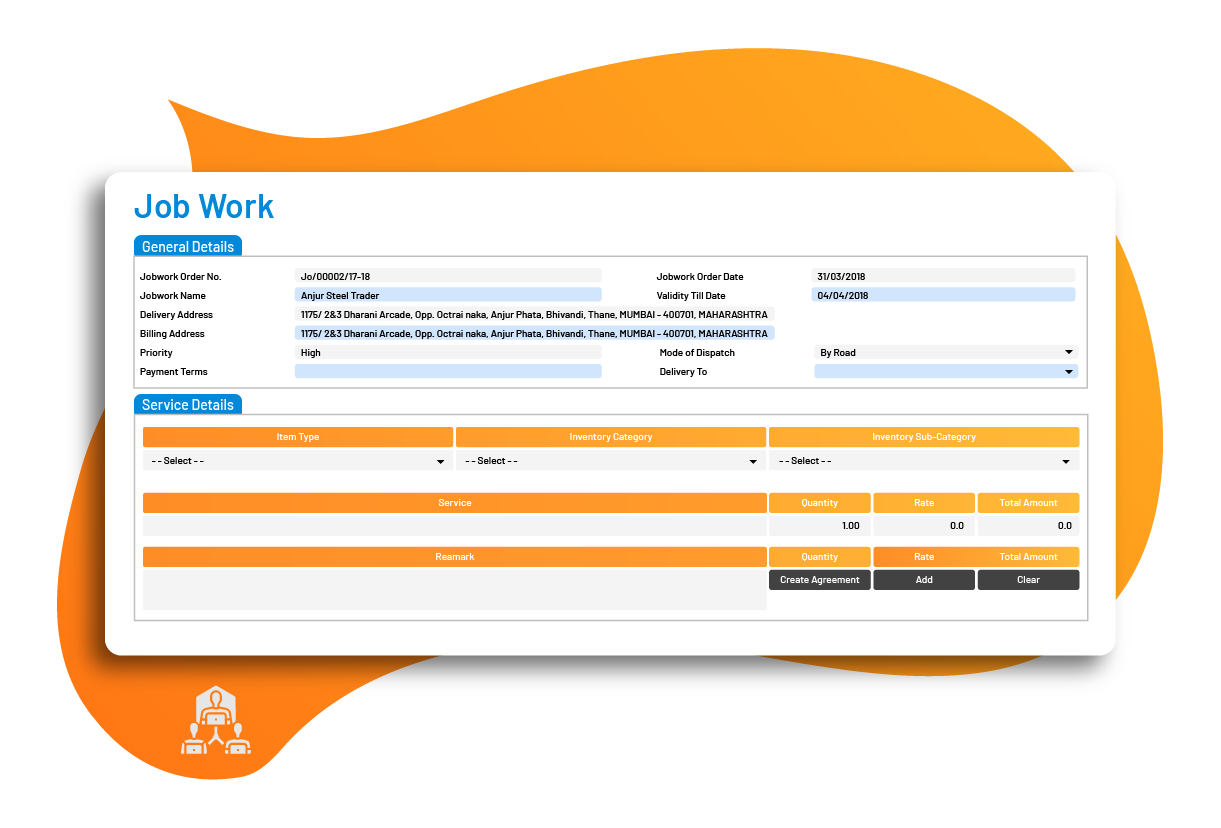

Job Work Management

Jobwork module in eresource is used to product any semi-finished goods or finish goods or any manufacturing activity to other workers outside the company to get the job done. Jobwork Management mod... Read More

Key Features

- Job Work Done by Job Work

- Service Master

- Job Work Order

- Job Work Material Requisition

- Job Work Material Issue

- Job Work Challan & Receipt

- Vendor Job-card Print

- Job Work Outward Invoice

- Job Work Done by Us

- In House Job Work Order

- Material Received & Dispatch Challan

- Job Work In House Invoice

-

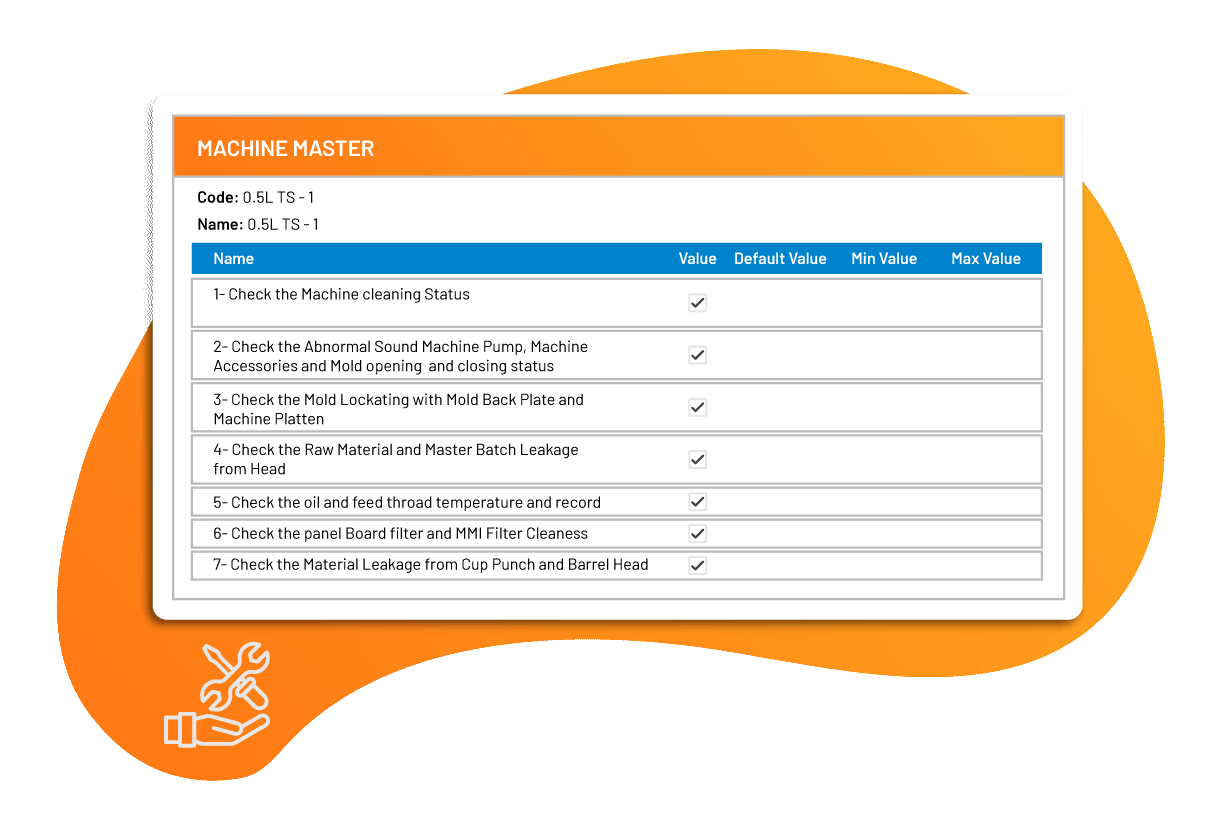

Plant Maintenance Management

Plant Maintenance is critical part of Manufacturing Operations Management. The functions of plant maintenance in eresource helps achieve minimum breakdown and keep the plant in good working conditi... Read More

Key Features

- Preventive Plan for Maintenance

- Calibration Schedule As Per Due Date

- Preventive Maintenance Log Sheet

- Calibration Certificate Update

- Break Down Maintenance Slip

- Break Down Handover Register

- Open Breakdowns for Maintenance

- Tool/Dies Changeover Register

- Preventive Plan – Machine Wise Checklist

- Asset List and Critical Spares List with ROL

-

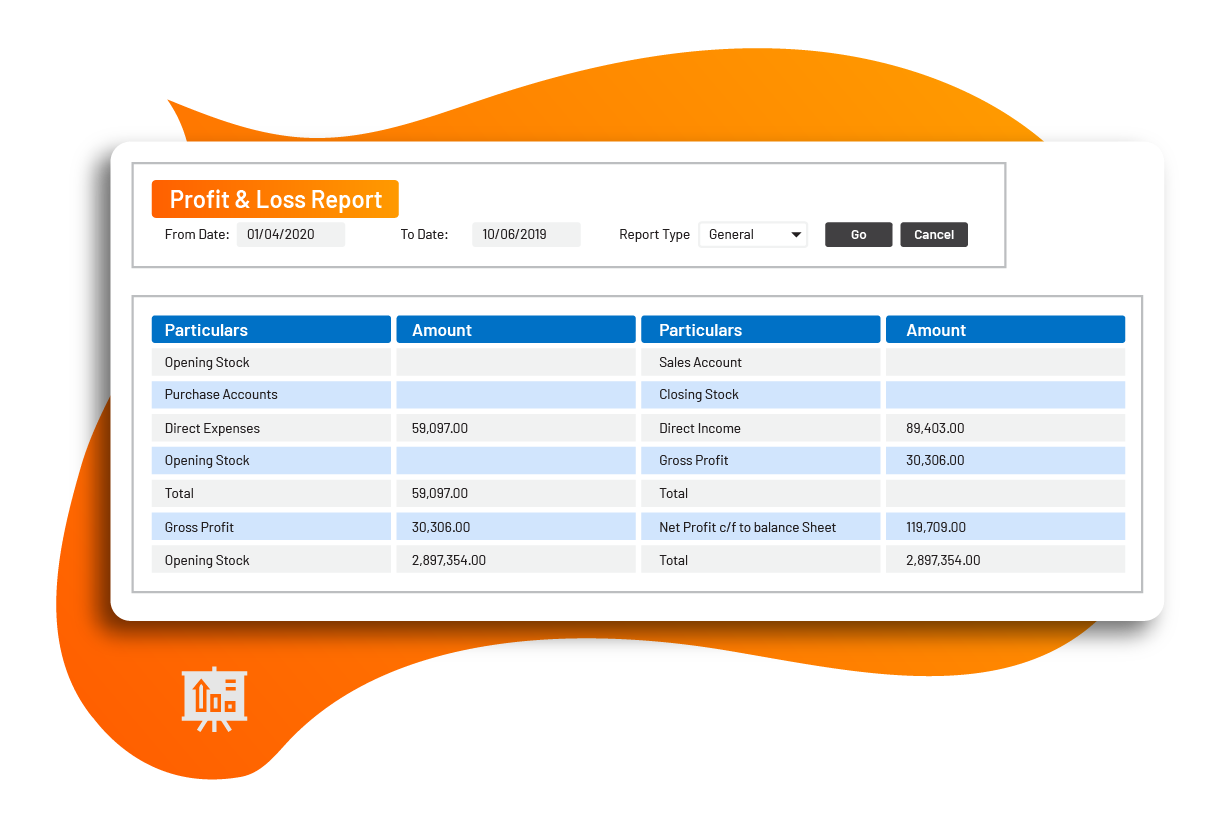

Accounts Management

Financial Accounting Module is a powerful financial management solution that enables you to manage your entire business profitably. The solution supports multiple currencies as well as complex mult... Read More

Key Features

- Group/Ledger Branch Relation

- Schedule 6 Main Head Setup

- Year wise Ledger Inactive

- Transfer Opening Balance

- GST Master

- Expense & Sales Voucher

- Debit note – Against Purchase Return

- Credit Note – Against Sales Return

- Bank/Cash Payable, Receivable

- Payable & Receivable Approve List

- Contract & Journal Approve List

- Invoice Register Branch Relation