ERP for Process

Manufacturing Industry

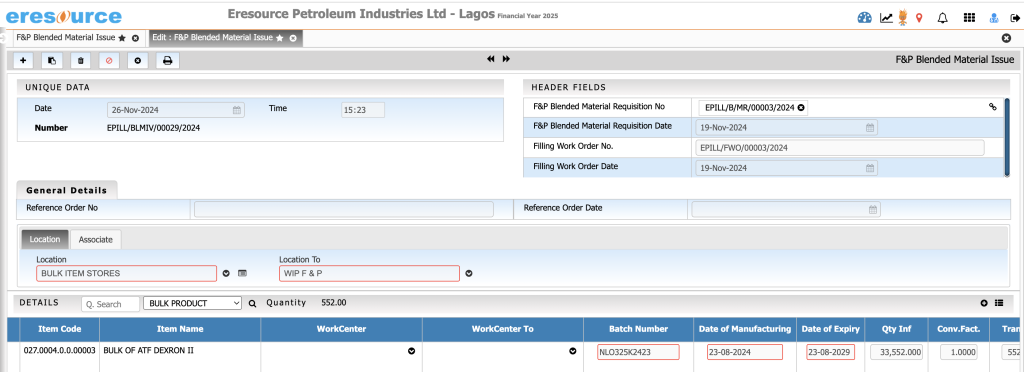

Process Manufacturing ERP Software for Batch Control, Compliance & Traceability

eresource BPRO ERP is purpose-built for process manufacturing industries that rely on batch accuracy, formulation control, and strict regulatory compliance. Designed for industries handling chemicals, pharmaceuticals, food, and formulations, BPRO ERP simplifies production, quality, inventory, and shelf-life management while ensuring full traceability.

From raw material intake to finished batch dispatch, BPRO ERP ensures every batch is compliant, efficient, and profitable.

What is Process Manufacturing ERP?

Process Manufacturing ERP is a specialized ERP system designed for industries where products are manufactured using formulas, recipes, or chemical processes instead of discrete assemblies. It manages batch production, formulation accuracy, quality testing, compliance, and shelf-life tracking within a single integrated platform.

Unlike generic ERP systems, a process manufacturing ERP handles batch traceability, potency-based inventory, regulatory documentation, and expiry-sensitive operations, making it essential for regulated and formulation-driven industries.

Process Manufacturing ERP Modules

Comprehensive modules designed specifically for batch-based and compliance-driven manufacturing operations.

Batch Management

Track batch-wise production with full traceability and yield control.

- Batch creation and auto-numbering

- Link batch with BOM and production run

- Batch status tracking (pending, in-process, completed)

- Yield vs target yield monitoring

- Waste and by-product capture

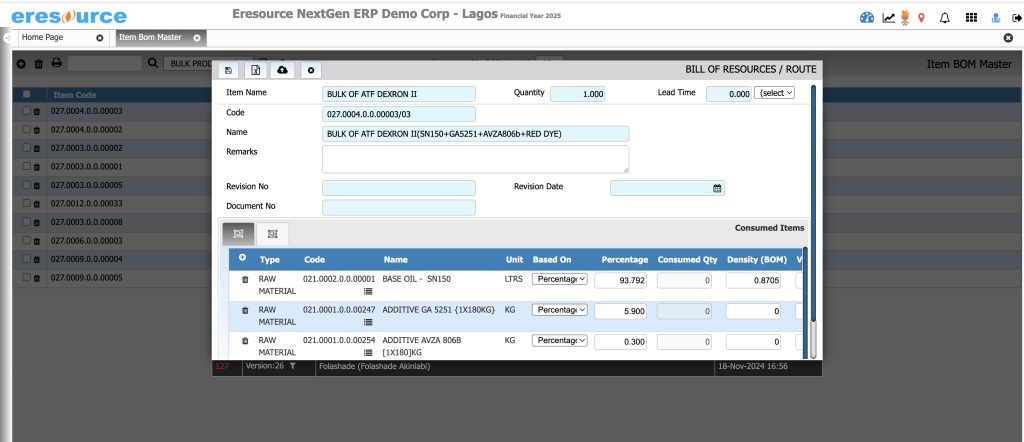

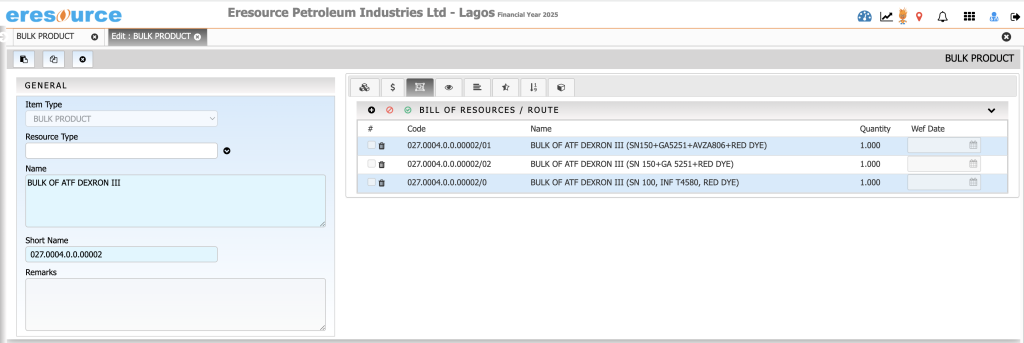

Recipe & Formula Management

Ensure formulation accuracy with controlled versioning and approvals.

- Multi-version recipe and formula management

- Strength, potency, and concentration setup

- Automatic quantity conversion during scale-up or scale-down

- Link formulas with regulatory specifications

- Approval workflows for formulation changes

Process Control

Maintain control over every stage of batch production.

- Define process steps with expected duration

- Monitor temperature, pressure, and processing time

- Operator checklists for each production stage

- Integration readiness with SCADA / PLC systems

- Alerts for deviations and out-of-range values

Quality Management

Manage quality across inward, in-process, and final inspection stages.

- Define QC parameters per material or process stage

- Sampling plans, test results, and document uploads

- Rejections, retesting, and disposition tracking

- Certificate of Analysis (CoA) generation

- Non-conformance reporting and CAPA logging

Production Planning

Plan batch production based on demand, capacity, and material availability.

- Batch planning calendar view

- Link production to sales orders or stock targets

- Automatic work order generation

- Capacity vs demand comparison

- Batch prioritization and sequencing

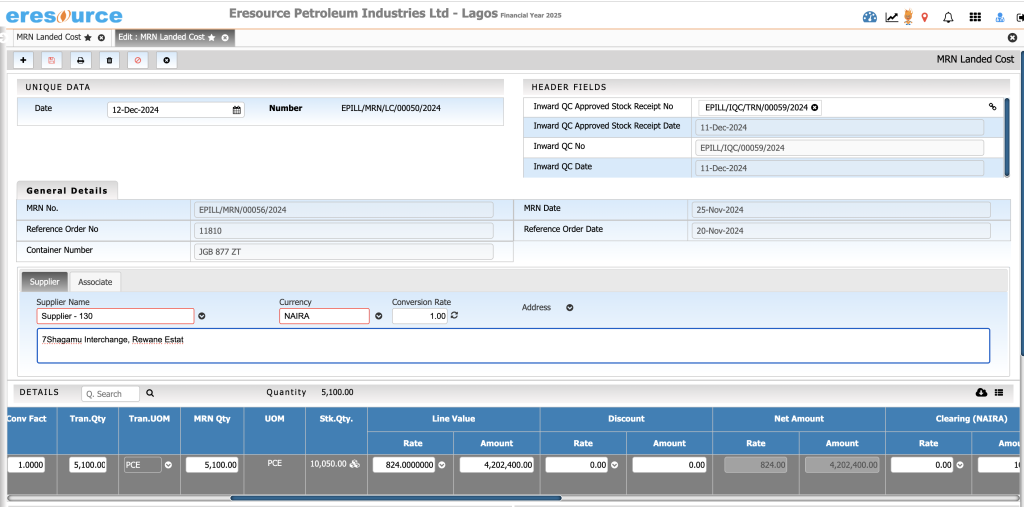

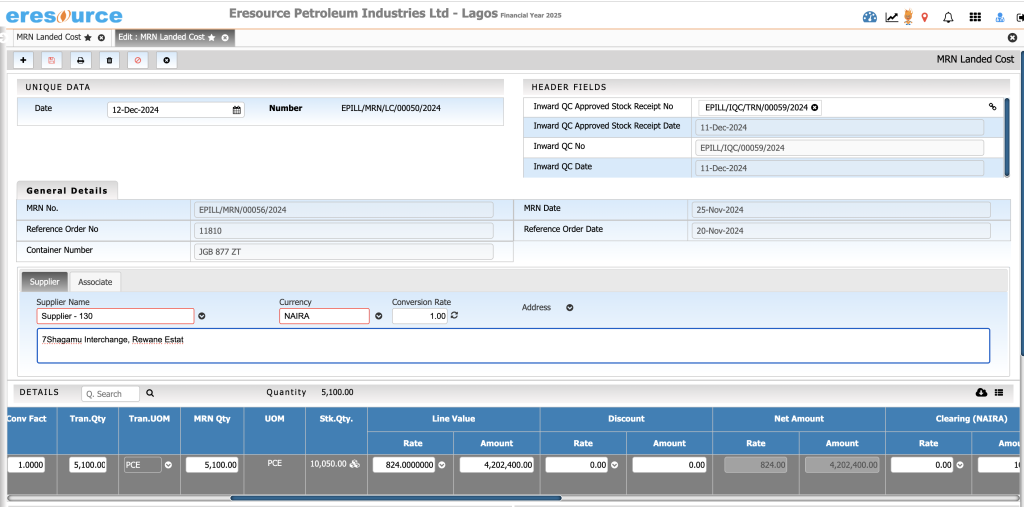

Raw Material Planning

Ensure materials are available when required without overstocking.

- Integrated MRP logic for process manufacturing

- Material availability vs requirement analysis

- Material reservation by batch or production run

- Auto purchase order suggestions

- MOQ and vendor lead-time consideration

Inventory & traceability

Track and control inventory by batch, potency, and QC status across locations.

- Lot, batch, and sub-batch traceability

- Expiry, shelf-life, and retest date tracking

- Potency and assay-based inventory control

- Multi-warehouse and bin-level management

- ABC analysis and stock ageing

Shelf Life & Expiry Tracking

Prevent losses and compliance risks from expired or near-expiry stock.

- Auto shelf-life calculation from batch date

- Alerts for near-expiry materials and products

- FIFO and FEFO picking rules

- Quarantine of expired batches

- Customer expiry and compliance certificates

Key Benefits of Process Manufacturing ERP

- Complete batch traceability from raw material to finished goods

- Accurate formulation and recipe management

- Reduced wastage and improved yield control

- Real-time quality monitoring and compliance reporting

- Shelf-life and expiry management with FEFO control

- Faster audits and regulatory readiness

- Improved production planning and inventory optimization

Who is this Process Manufacturing ERP Best suited for?

eresource Bpro ERP is ideal for manufacturers operating in regulated and formulation-driven environments.

- Pharmaceutical manufacturers

- Bulk drug and API manufacturers

- Food and beverage producers

- Chemical and solvent manufacturers

- Paints and coatings manufacturers

- Cosmetics and personal care brands

- Detergents and cleaning product manufacturers

- Agro-chemical producers

- Oil, lubricants, and specialty chemical companies

Industry-Specific Process Manufacturing ERP Solutions

Trusted by process manufacturing companies across regulated industries.

Process Manufacturing ERP Dashboards

Gain complete visibility into batch performance, quality trends, compliance status, and inventory health.

IoT Integration for Process Manufacturing

Connect equipment and sensors to ERP for automated data capture and predictive insights.

- Capture real-time sensor data (temperature, pressure, time)

- Auto logging from mixers, tanks, and reactors

- Predict equipment failure using trend analysis

- Trigger alerts for deviations

- Reduce manual data recording

Mobile Access for Process Manufacturing Teams

Access critical production and quality data on the move.

- Shopfloor data entry via mobile

- QC checklist and inspection entry

- Barcode scanning using mobile camera

- View dashboards on mobile devices

- Role-based approvals and access

Faster ERP Implementation with Low-Code / No-Code Framework

eresource Bpro ERP is built on a low-code / no-code platform that accelerates implementation and simplifies customization.

- Built on Low Code / No Code platform

- Go-live in as little as 90 days

- Drag-and-drop workflow configurator

- No dependency on developers for changes

- Perfect for growing or large project companies

Why choose eresource Bpro ERP for Process Manufacturing?

eresource Bpro ERP is built with a deep understanding of process manufacturing challenges.

- Designed specifically for batch and formulation-based industries

- Strong focus on compliance, traceability, and audits

- Advanced batch, recipe, and quality control capabilities

- Shelf-life, potency, and expiry-aware inventory

- Faster implementation using low-code technology

- Flexible deployment: cloud or on-premise

Process Manufacturing ERP Comparison

A high-level comparison to help you evaluate the right ERP for process manufacturing needs.

| Criteria | eresource Bpro ERP | Zoho ERP | SAP ERP | Dynamic ERP |

| Core Focus | Process & batch manufacturing | General ERP | Enterprise ERP | SME ERP |

| Batch & Recipe Management | Deep, industry-specific | Limited | Available but complex | Basic |

| Compliance & Traceability | Strong | Limited | Strong | Moderate |

| Shelf-Life & Expiry Control | Advanced | Limited | Available | Basic |

| Customization | High (Low-Code / No-Code) | Limited | High but costly | Limited |

| Implementation Speed | Faster (30–90 days) | Quick for small use | Long | Moderate |

| Best Suited For | Small to large process manufacturers | Small businesses | Large enterprises | Small manufacturers |

| Deployment | Cloud & On-Premise | Cloud | Cloud & On-Premise | Mostly On-Premise |

Success Stories

Process and industrial manufacturers trust eresource ERP to improve compliance, efficiency, and control.

Bulk Drug Mfg

Before → After Impact

Chemical & Additive Mfg

Before → After Impact

Oil & Lubricant Mfg

Before → After Impact

Plastic Mfg

Before → After Impact

Trusted by Industrial and Manufacturing Businesses

We are extremely happy to be associated with eresource. They have done an excellent job by providing us a fantastic ERP system. Right from the beginning we knew that we have made the right decision in choosing eresource.

Our company is using eresource ERP for the last six years and it make us happy that we have an effective enterprise solution in place for all our business processes. The visibility of information is helping our managers to take timely decisions.

Video Resources

Explore how AI-driven ERP, batch tracking, and compliance automation are transforming process manufacturing.

Revolutionise Your Pharma Operations with eresource ERP: Here’s How!

Why Rubber Manufacturers are switching to Smarter ERP Systems | Rubber Moulding ERP

Best ERP for Oil & Lubricants Manufacturers | Batch Manufacturing AI Driven ERP

Explained: Why Your Pharmaceutical Business Needs ERP? | Pharmaceutical ERP

Frequently

Asked Question

Get answers to common questions about Process Manufacturing ERP

Why eresource Nfra?

eresource Nfra is an all-in-one ERP software designed for the construction industry, replacing multiple tools by streamlining project planning, estimation, scheduling, and more; trusted by leading firms across India, the Gulf, and Africa.

What are the benefits of eresource Nfra?

eresource Nfra offers a cost-effective, cloud-based ERP solution with automated administration, mobile compatibility, digital documentation, streamlined modules, and anytime-anywhere access – boosting productivity, operational excellence, and ROI for construction businesses.

Is eresource Nfra mobile version available?

Yes, eresource Nfra offers a fully mobile-compatible ERP application, allowing users to access, share, and update project data in real-time from any smartphone, enhancing connectivity and quick decision-making on the go.

How does Construction ERP help in project management and cost control?

Construction ERP like eresource Nfra streamlines project management by centralizing data, enabling real-time cost monitoring, automated billing and financial forecasting, helping reduce overruns and improve overall profitability.

Can Construction ERP Software be customized for specific business needs?

Yes, most Construction ERP solutions like eresource Nfra are highly customizable and modular, enabling businesses to tailor features according to their specific operational needs.

Is Construction ERP Software suitable for small construction businesses?

Yes, Construction ERP Software can be scaled to suit the needs of small, medium, or large construction businesses, offering tailored modules that match their project size and budget.

How long does it take to implement Construction ERP Software?

Implementation of Construction ERP Software can take anywhere from a few weeks to several months, depending on the complexity, customization needs, and user training involved.